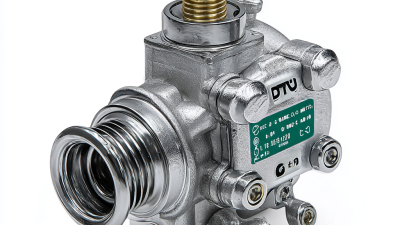

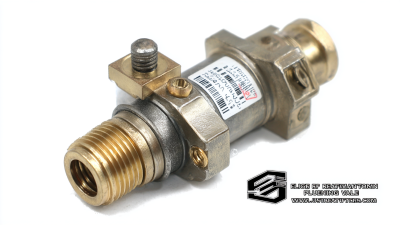

Understanding the Functionality of Air Flow Control Valves

Air Flow Control Valves play a crucial role in various industrial applications, regulating the amount of air that flows through a system to ensure optimal performance and efficiency. According to a recent report by Research and Markets, the global market for air flow control valves is projected to grow at a CAGR of 4.5% from 2021 to 2026, driven by the increasing demand for energy-efficient systems in HVAC applications and process industries. As industries strive for sustainability and improved operational efficiency, understanding the functionality of these valves becomes essential.

This tutorial aims to provide a comprehensive overview of how Air Flow Control Valves operate, their types, applications, and best practices for selection and maintenance, equipping you with the knowledge necessary to optimize their use in your projects.

The Essential Role of Air Flow Control Valves in HVAC Systems

Air flow control valves play a crucial role in HVAC systems, significantly affecting both energy efficiency and indoor air quality. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), properly regulated air flow can lead to energy savings of up to 30% in commercial buildings. These valves enable precise adjustments to air flow, ensuring that spaces are neither overheated nor overcooled, which is essential for maintaining comfort and reducing energy consumption.

In modern HVAC systems, the integration of air flow control valves allows for enhanced zone control. A report from the U.S. Department of Energy highlights that systems utilizing variable air volume (VAV) technology, which relies heavily on these valves, are able to improve thermal comfort while reducing operational costs. By adjusting the air supply based on real-time demand, these valves contribute to a more sustainable system overall. The result is not only improved occupant comfort but also reductions in greenhouse gas emissions, aligning with global efforts to create more energy-efficient buildings.

5 Key Benefits of Air Flow Control Valves for Energy Efficiency

Air flow control valves play a crucial role in enhancing energy efficiency within various systems. One of the primary benefits of these valves is their capability to maintain optimal air flow, which reduces unnecessary strain on HVAC systems. By adjusting air volume based on the demand, these valves ensure that energy is not wasted, leading to lower utility bills and a reduced carbon footprint.

Another key advantage is their contribution to improved indoor air quality. By effectively regulating air flow, these valves help prevent the buildup of stale air and allergens, promoting a healthier environment. Furthermore, maintaining consistent air flow contributes to improved temperature regulation, ensuring that spaces remain comfortable without excessive energy consumption. This balance not only optimizes energy use but also enhances overall occupant satisfaction, making air flow control valves essential components in modern energy-efficient systems.

Understanding Pressure Drop and Air Flow Optimization in Duct Systems

Air flow optimization is a critical aspect of designing effective duct systems, especially when considering pressure drop. Pressure drop refers to the loss of pressure that occurs as air flows through the ducts, and it can significantly impact the efficiency of HVAC systems. Understanding how various components within the ductwork, including bends, filters, and dampers, contribute to pressure drop can help in selecting the right air flow control valves to mitigate these losses.

Efficient air flow control valves play a vital role in maintaining desired pressure levels and optimizing air distribution. By adjusting the flow of air within the duct system, these valves can reduce the energy required to maintain comfortable indoor conditions. Properly sized and positioned valves ensure balanced air flow, minimizing areas of stagnation and improving circulation. Implementing advanced control strategies alongside these valves can further enhance performance, ensuring that air reaches every part of the space effectively while reducing the energy consumption associated with overcoming pressure drops.

Understanding the Functionality of Air Flow Control Valves

| Valve Type | Pressure Drop (inches WC) | Air Flow Rate (CFM) | Application |

|---|---|---|---|

| Butterfly Valve | 0.3 | 650 | HVAC Systems |

| Globe Valve | 0.5 | 500 | Industrial Ventilation |

| Dampers | 0.2 | 800 | Air Distribution |

| Control Valve | 0.4 | 600 | Temperature Control |

Accurate Sizing and Selection of Air Flow Control Valves: Best Practices

When it comes to achieving optimal performance in various systems, the accurate sizing and selection of air flow control valves are crucial. Proper sizing ensures that the valves can handle the desired flow rates without causing turbulence or pressure drops. It's essential to consider the system's specifications, including the maximum and minimum flow requirements, to prevent operational inefficiencies.

**Tip 1:** Utilize manufacturer guidelines to understand the key parameters for sizing valves. Look for data sheets that provide flow characteristics and sizing equations to help you make informed decisions based on your specific application.

In addition to sizing, selecting the right type of valve is equally important. Different applications may require different valve types such as pressure-regulating valves, modulating valves, or on-off valves. Understanding the purpose the valve serves within the system will guide your selection process.

**Tip 2:** Assess the environmental conditions, such as temperature and humidity, as these factors can influence valve performance. Selecting a valve that is not only appropriately sized but also suitable for the specific operating conditions can significantly enhance system efficiency and reliability.

Recent Innovations in Air Flow Control Valve Technology and Industry Standards

Recent advancements in air flow control valve technology have dramatically enhanced efficiency and performance across various industrial applications. According to a report by the International Society of Automation (ISA), innovations in valve design, including smart actuators and advanced materials, have led to a 25% reduction in energy consumption for HVAC systems. These new technologies not only improve precision in flow regulation but also enhance the overall reliability of systems that depend on consistent air flow.

Tips: Consider evaluating your current air flow control systems for compatibility with the latest technology. Regular maintenance checks and upgrades can enhance operational efficiency and energy savings. Additionally, staying informed about industry standards can help ensure compliance and optimize performance in your facility.

Related Posts

-

Innovative Air Flow Control Valve Solutions Spotlighted at Expanding International Market During 137th Canton Fair

-

Ultimate Guide to Choosing the Best Hydraulic Pressure Regulator for Your Needs

-

Finding the Perfect Supplier for Best Pneumatic Control Valves Your Comprehensive Guide

-

Championing Excellence in China The Best Steam Pressure Reducing Valve Export Leader

-

Discover Elite Manufacturing from a Leading Chinese Factory: Your Source for the Best Pressure Reducing Valve

-

Unmatched Innovation in Best Air Flow Control Valves from China's Leading Manufacturing Plants