Top Benefits of Die Casting Molds for Manufacturing?

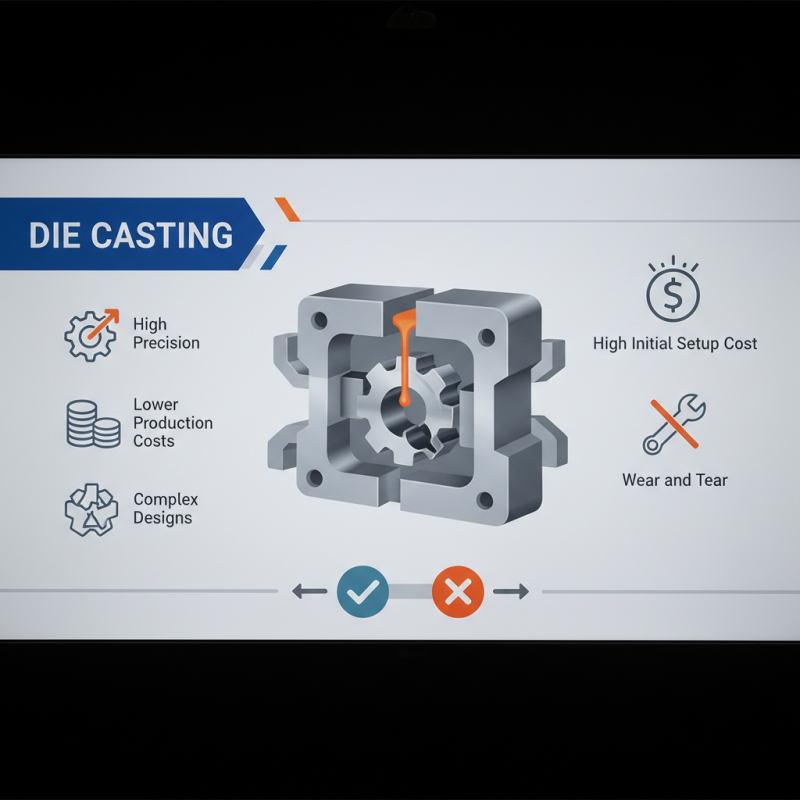

Die Casting Molds play a vital role in the manufacturing industry. They allow for the mass production of intricate parts with high precision. These molds are crafted from durable materials, ensuring they withstand high pressure and temperature during the casting process.

The benefits of using die casting molds are numerous. They consistently produce high-quality parts, reducing the need for extensive post-processing. This not only saves time but also lowers production costs. Manufacturers often appreciate the ability to create complex designs that are difficult to achieve with other methods.

Despite their advantages, challenges exist. The initial setup cost for die casting molds can be high. Additionally, if not maintained properly, molds can suffer from wear and tear. Regular inspections and careful management help maintain quality. Overall, die casting molds offer significant advantages in manufacturing, but companies must navigate the associated challenges.

Advantages of Die Casting Molds in Precision Manufacturing Processes

Die casting molds play a crucial role in precision manufacturing. They allow for the creation of intricate shapes and designs with high accuracy. The process can produce complex parts in a single step, minimizing any assembly time. This efficiency can lead to lower production costs over time, a significant advantage for manufacturers.

Working with die casting molds does come with its challenges. The initial costs for mold design and production can be high. There’s also a risk of defects in the casting process if the molds are not maintained properly. However, when executed correctly, these molds ensure consistent quality. They offer a reliable solution for industries needing precision parts. The ability to produce lightweight yet durable components makes die casting molds ideal for automotive and aerospace applications.

Moreover, the versatility of die casting molds cannot be overlooked. They can accommodate various materials, enhancing the range of applications. Manufacturers often experiment with different alloys for better performance. This exploration can lead to unexpected results, requiring constant adjustment and improvement of processes. It’s a journey where precision meets innovation, but it demands commitment to quality and detail.

Top Benefits of Die Casting Molds for Manufacturing

| Benefit | Description | Applications |

|---|---|---|

| High Precision | Die casting molds produce parts with tight tolerances, ensuring high dimensional accuracy. | Automotive components, electronics housings |

| Cost Efficiency | Reduces material waste and production costs through efficient mold designs. | Mass production of metal parts |

| Durability | Molds are made from durable materials, resulting in longer service life and fewer replacements. | Heavy machinery, aerospace components |

| Complex Geometries | Ability to create complex and intricate designs that would be difficult to achieve with other methods. | Consumer goods, industrial products |

| Fast Production Rates | High volume production capabilities with quick cycle times increase output. | High-demand consumer markets |

Cost-Effectiveness: Reducing Production Expenses with Die Casting Molds

Die casting molds are cost-effective for manufacturers. They streamline production while cutting expenses. According to a recent industry report, die casting can reduce labor costs by up to 30%. This efficiency allows companies to allocate resources better.

The initial investment in die casting molds can seem high. However, the long-term savings are significant. Molds can produce thousands of parts with minimal maintenance. A well-maintained mold lasts longer than other production methods too. Some molds can reach a lifespan of over 1 million cycles, minimizing replacement costs.

Despite these advantages, companies must consider the accuracy of their designs. Miscalculations can lead to flawed products. A mistake in the mold design might result in wasted materials and time. It’s crucial to invest in precise modeling and simulations. Manufacturers should strive for continuous improvement to maximize the potential of die casting molds.

Enhancing Product Quality: The Role of Die Casting in Reducing Defects

Die casting plays a crucial role in enhancing product quality by significantly reducing defects. In the manufacturing sector, data indicates that die casting defects can be as low as 1% in well-managed processes. This reduction is essential for companies aiming for high precision and consistency in their products. For instance, the American Foundry Society reported that the die casting method can achieve tolerances of ±0.005 inches, improving overall product reliability.

Moreover, die casting molds facilitate uniformity and repeatability. Each mold can produce thousands of identical parts, ensuring that deviations in quality are minimized. Finishing processes, like shot blasting or coating, complement the die casting approach to further enhance surface quality. However, it’s important to acknowledge that not every die casting process is flawless. Issues such as internal porosity or exact dimensionality can occur. Manufacturers must continually assess their techniques and invest in advanced technologies to mitigate these imperfections.

The integration of machine learning and statistical process control can enhance defect detection. Recent studies have shown that real-time monitoring can reduce defects by up to 30%. By analyzing production data and adjusting accordingly, manufacturers can not only save costs but also elevate the quality of their output. Each step taken to refine die casting processes reflects a commitment to superior production standards.

Material Versatility: A Range of Alloys for Diverse Applications in Die Casting

Die casting molds have revolutionized manufacturing due to their versatility. Various alloys can be employed, each offering unique properties. For instance, aluminum alloys are lightweight and resistant to corrosion. They work well in automotive and aerospace applications. Zinc alloys, on the other hand, excel in strength and ease of machining. They are often used in electronics and appliance components.

Material selection is crucial in die casting. Not every alloy suits every application. Some materials may fail to meet required strength or thermal resistance. Manufacturers need to analyze their specific needs carefully. The wrong choice can lead to costly failures or inefficiencies. The flexibility of die casting molds allows for adjustments, but knowing the material limits is essential. It is a process of constant learning and improvement, driven by trial and error.

Speed and Efficiency: Faster Production Cycles with Die Casting Technology

Die casting technology revolutionizes manufacturing with its speed and efficiency. This process allows for rapid production of complex shapes. Molds are often made from high-quality materials, ensuring durability. As a result, companies can meet tight deadlines more effectively. The quick turnaround time significantly reduces the overall cycle of production.

Tip: Select the right alloy. Different alloys can influence the die’s performance and product quality. A slight miscalculation here can lead to defects.

Furthermore, die casting enables high-volume production without compromising precision. Parts produced maintain tight tolerances, which is crucial in industries like automotive and aerospace. However, designing molds can be challenging. Small errors can lead to costly reworks. A close inspection of mold designs is essential.

Tip: Regular maintenance of molds can extend their lifecycle. Ignoring this can lead to increased costs down the line.

Focusing on efficiency is vital in this high-demand landscape. But overlooking details can be detrimental. Balancing speed and quality is a constant challenge. Utilizing advanced simulation technologies can help minimize risks during the design phase.