Choosing Quality Manufacturers for the Best Steam Pressure Reducing Valve Solutions

In the rapidly evolving industrial landscape of 2025, the demand for reliable and efficient Steam Pressure Reducing Valves has never been more critical. These essential components play a pivotal role in regulating steam pressure within various applications, ensuring safety and operational efficiency. As manufacturers strive to meet these growing demands, selecting high-quality producers becomes paramount. The choice of a reputable manufacturer influences not only the performance of the Steam Pressure Reducing Valve but also impacts overall system integrity and longevity. This blog delves into the key factors to consider when choosing quality manufacturers, exploring the technological trends that define the industry and how they can facilitate optimal valve solutions for modern applications. As we navigate through the complexities of the manufacturing landscape, understanding these aspects will empower businesses to make informed decisions, ultimately leading to enhanced performance and reliability in their steam systems.

Factors to Consider When Selecting a Quality Steam Pressure Reducing Valve Manufacturer

When selecting a quality steam pressure reducing valve manufacturer, it is crucial to consider several key factors to ensure optimal performance and reliability. First and foremost, manufacturers should be evaluated based on their industry certifications and compliance with relevant standards, such as ASME and ISO. According to a report by the International Steam Heating Association, proper certification often correlates with higher quality products and improved safety features, reducing the risk of operational failures.

Another important factor is the experience and reputation of the manufacturer in the market. A study conducted by the Engineering Industry Association found that manufacturers with over 20 years of experience tend to have a more profound understanding of customer needs and the technological advancements in steam systems. Reviews and case studies can provide insights into a manufacturer’s capability to deliver high-quality products that meet specific performance requirements.

**Tip:** Always request references or case studies from the manufacturer to assess their capacity to meet industry demands effectively.

Additionally, attention should be paid to the technology and materials used in production. Cutting-edge manufacturing processes and high-grade materials significantly enhance the durability and efficiency of steam pressure reducing valves. Research indicates that valves made from advanced alloys can withstand higher pressure fluctuations and temperatures, ultimately extending their service life.

**Tip:** Assess the warranty and after-sales support offered; a robust support system can drastically reduce downtime in case of issues.

Understanding the Importance of Certification and Compliance in Valve Production

When selecting manufacturers for steam pressure reducing valves, it's essential to prioritize certification and compliance within their production processes. Certified manufacturers adhere to strict industry standards, which ensures the safety and reliability of their products. Compliance with regulations not only protects users from potential hazards but also enhances the overall functionality of the valve systems used in various applications, from industrial settings to commercial spaces.

Tip: When evaluating a manufacturer, request information on their certifications. Look for compliance with standards like ISO 9001, which indicates a commitment to quality management systems. Additionally, verify that they meet specific industry regulations pertinent to your region and application.

Understanding the implications of non-compliance is crucial. Using valves from manufacturers without proper certifications can lead to significant operational risks, including safety failures and expensive downtime. Selecting the right partner means opting for a manufacturer that prioritizes quality control and adheres to compliance processes, thus ensuring the longevity and performance of your steam pressure reducing valves.

Tip: Always seek manufacturers that are transparent about their certification processes and willing to provide documentation. This not only builds trust but also gives you confidence in the quality of your valve solutions.

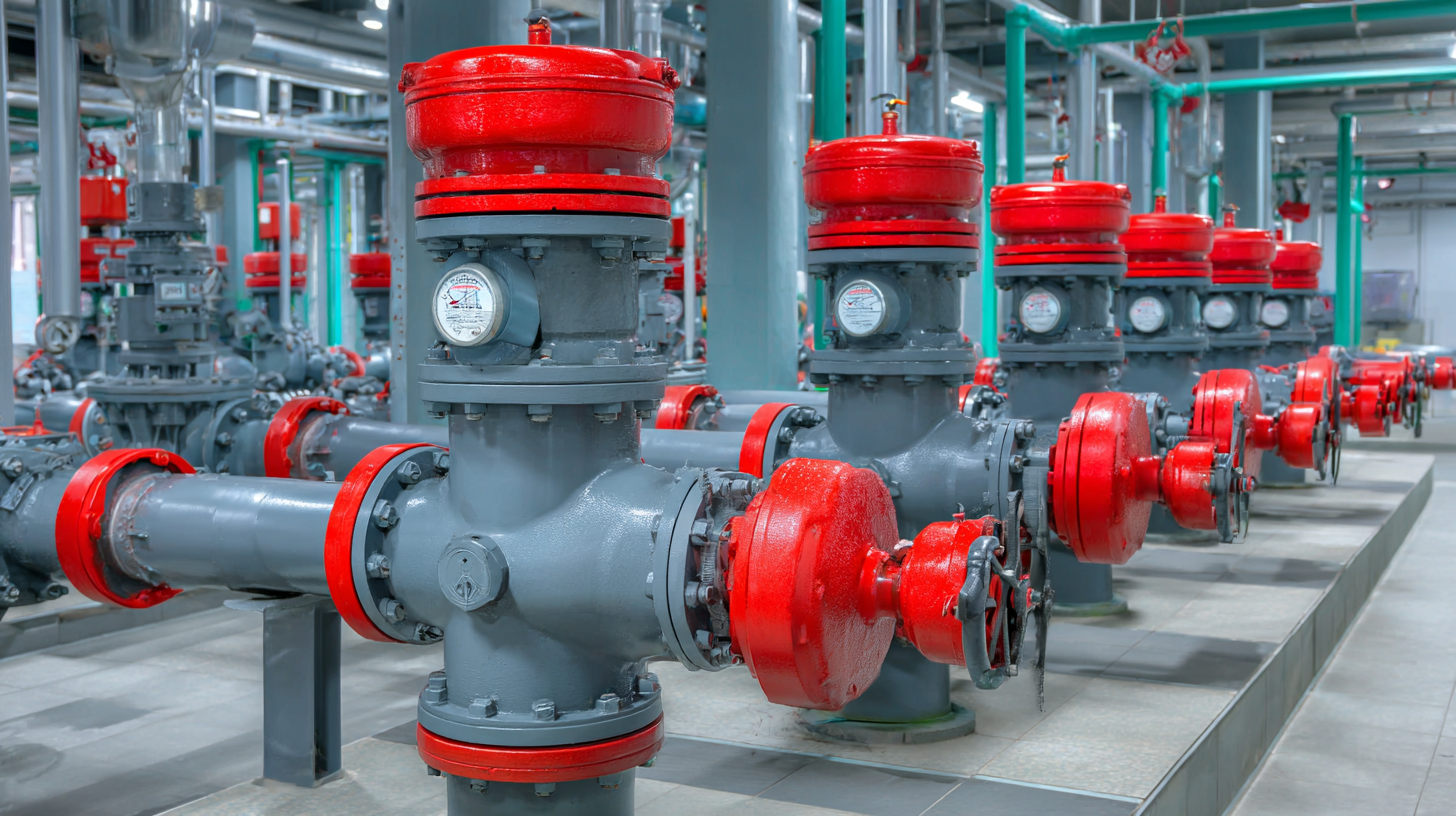

Steam Pressure Reducing Valve Solutions: Quality Manufacturers Certification Compliance

Evaluating Manufacturer Performance: Key Metrics and Industry Standards

When choosing quality manufacturers for steam pressure reducing valves, evaluating manufacturer performance through key metrics and industry standards is critical. According to a recent market report by Technavio, the global steam valve market is projected to exceed $11 billion by 2026, with a compound annual growth rate (CAGR) of over 4%. This growth underscores the need for manufacturers to meet stringent performance benchmarks to remain competitive. Essential metrics to consider include lead times, product durability, and compliance with safety standards like ISO 9001, which guarantees consistent quality management processes.

In addition, it is vital to assess manufacturers based on their innovation capabilities and customer support services. A report from MarketsandMarkets highlights that 75% of buyers prioritize manufacturers that demonstrate continuous innovation and effective communication. Evaluating these aspects will not only help in finding high-quality steam pressure reducing valves but will also ensure that the chosen manufacturer can adapt to industry trends and provide reliable after-sales support. Such evaluations contribute significantly to a manufacturer’s reputation and the long-term satisfaction of end-users.

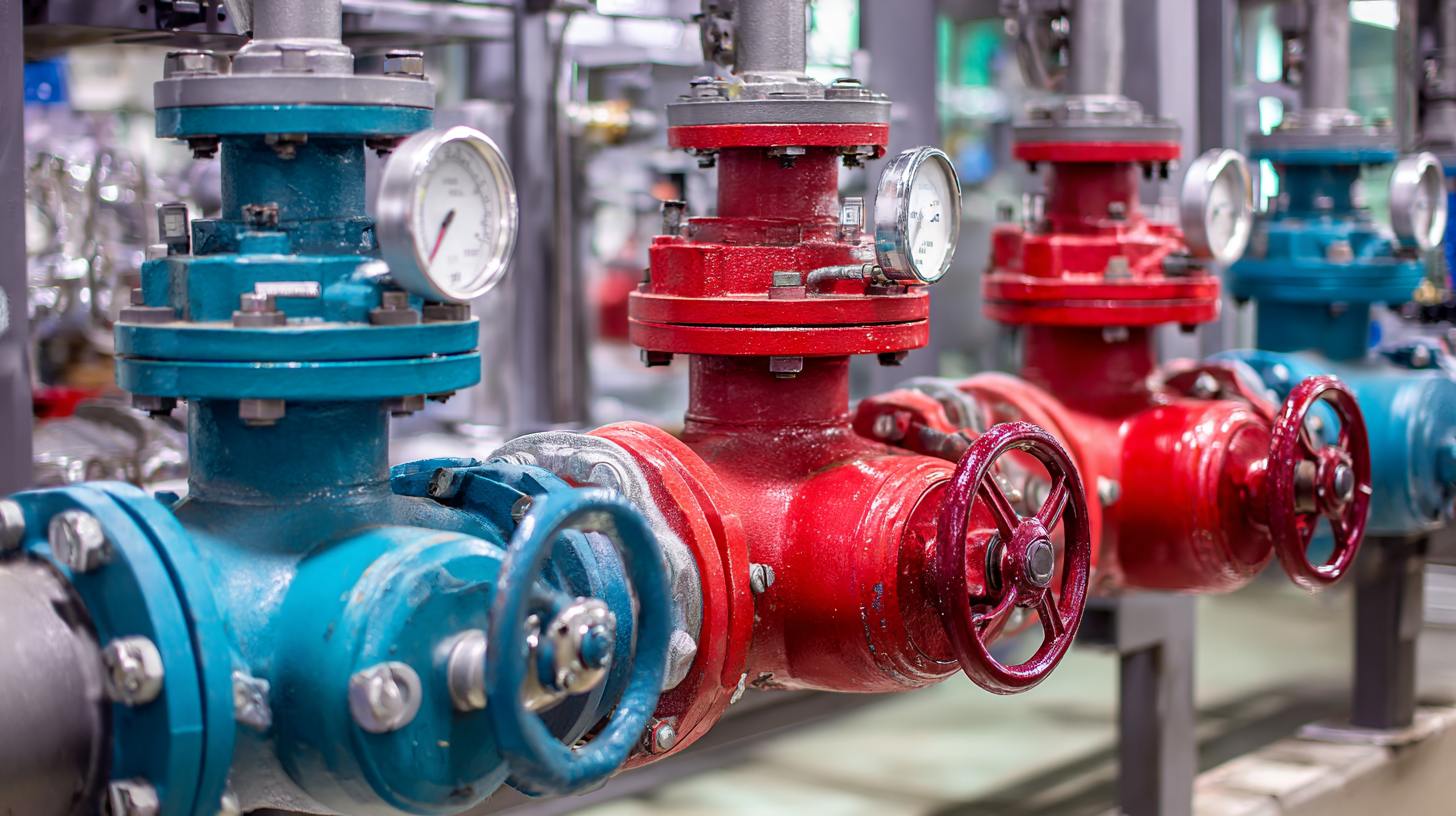

Choosing Quality Manufacturers for the Best Steam Pressure Reducing Valve Solutions - Evaluating Manufacturer Performance: Key Metrics and Industry Standards

| Metric | Description | Industry Standard | Manufacturer Performance |

|---|---|---|---|

| Quality Assurance | The processes for maintaining quality standards through regular checks and balances. | ISO 9001 Certification | Certified |

| Customer Satisfaction | Feedback and ratings from clients regarding product performance and service. | ≥ 90% Positive Feedback | 85% |

| Lead Time | The time taken from order placement to delivery. | ≤ 4 Weeks | 5 Weeks |

| Product Testing | Evaluation of product performance against design specifications. | 95% Pass Rate | 92% |

| Cost Competitiveness | Pricing compared to industry averages for similar products. | Within 10% of Average | 15% Above Average |

Global Market Trends: How China's Manufacturing Dominance Impacts Valve Solutions

The global market for steam pressure reducing valves (PRVs) is heavily influenced by China’s manufacturing prowess. As the world’s largest producer of industrial valves, China has established itself as a key player in the supply chain, utilizing advanced technologies and cost-effective production methods. This dominance enables Chinese manufacturers to offer competitive pricing and a wide range of products that meet international standards, allowing companies across various sectors to access high-quality valve solutions.

However, the impact of China's manufacturing strength extends beyond just competitive pricing. As Chinese companies increasingly invest in research and development, they are leading innovations in valve technology, enhancing efficiency and reliability. This trend not only boosts the global availability of advanced steam pressure reducing valves but also raises the bar for quality across the industry. For businesses seeking to source quality manufacturers, understanding the dynamics of the Chinese market is essential for making informed decisions that align with their operational needs and long-term objectives.

Cost-Benefit Analysis: Investing in High-Quality vs. Low-Cost Steam Pressure Reducing Valves

When it comes to selecting steam pressure reducing valves, a cost-benefit analysis is essential for making an informed decision. While low-cost options may seem attractive initially, they often come with hidden expenses such as higher maintenance costs, increased operational downtime, and potential safety risks. Investing in high-quality valves may require a larger upfront expenditure but can lead to substantial savings over time through improved reliability and efficiency.

Tip 1: Consider the total cost of ownership rather than just the purchase price. Evaluate long-term benefits, including reduced energy consumption and lower maintenance expenses, which are often associated with high-quality products.

High-quality steam pressure reducing valves are designed to endure extreme operating conditions and deliver consistent performance. This reliability not only enhances operational efficiency but also contributes to safety in your facility. Opting for reputable manufacturers can provide additional benefits like warranties and customer support, giving you peace of mind.

Tip 2: Research manufacturer reputation and customer reviews before making a purchase. A trusted manufacturer often guarantees product quality and service, which is crucial for long-term operational success.