Ultimate Guide to Choosing the Best Hydraulic Pressure Regulator for Your Needs

In today's rapidly evolving industrial landscape, selecting the right Hydraulic Pressure Regulator is crucial for optimizing system performance and ensuring operational efficiency. As we look toward the technological advancements of 2025, it is essential to understand the various types of hydraulic pressure regulators available and how they can benefit different applications. Whether you're dealing with precision machinery, heavy equipment, or dynamic hydraulic systems, a well-chosen pressure regulator plays a pivotal role in maintaining consistent pressure levels, enhancing safety, and reducing energy costs. This guide aims to equip you with the knowledge necessary to navigate the complexities of hydraulic pressure regulation, highlighting the latest innovations and trends that will shape the future of this critical component. Join us as we explore the benefits of various types of hydraulic pressure regulators and how to tailor your choice to meet your specific needs.

Understanding Hydraulic Pressure Regulators: Key Features and Functions

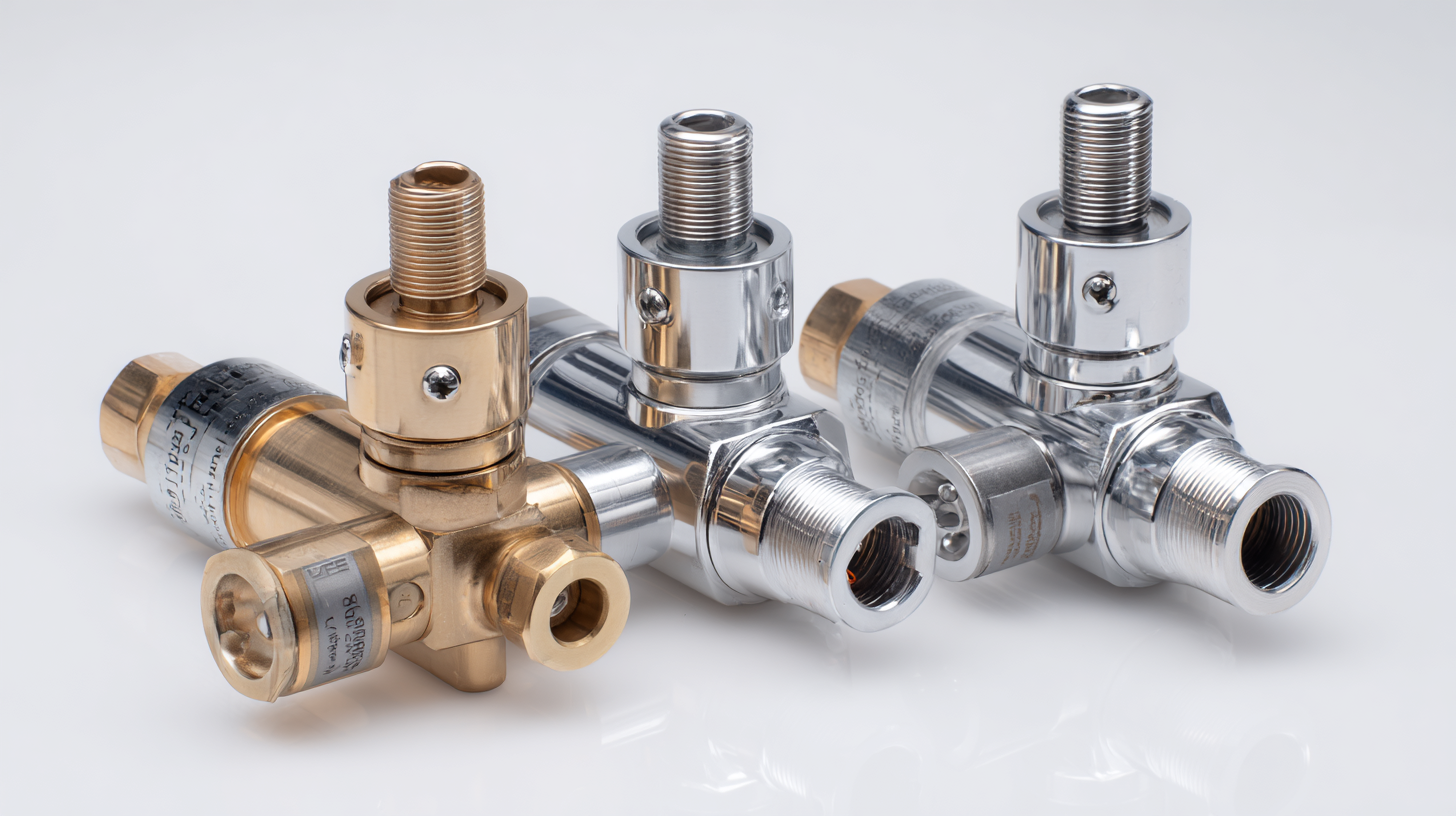

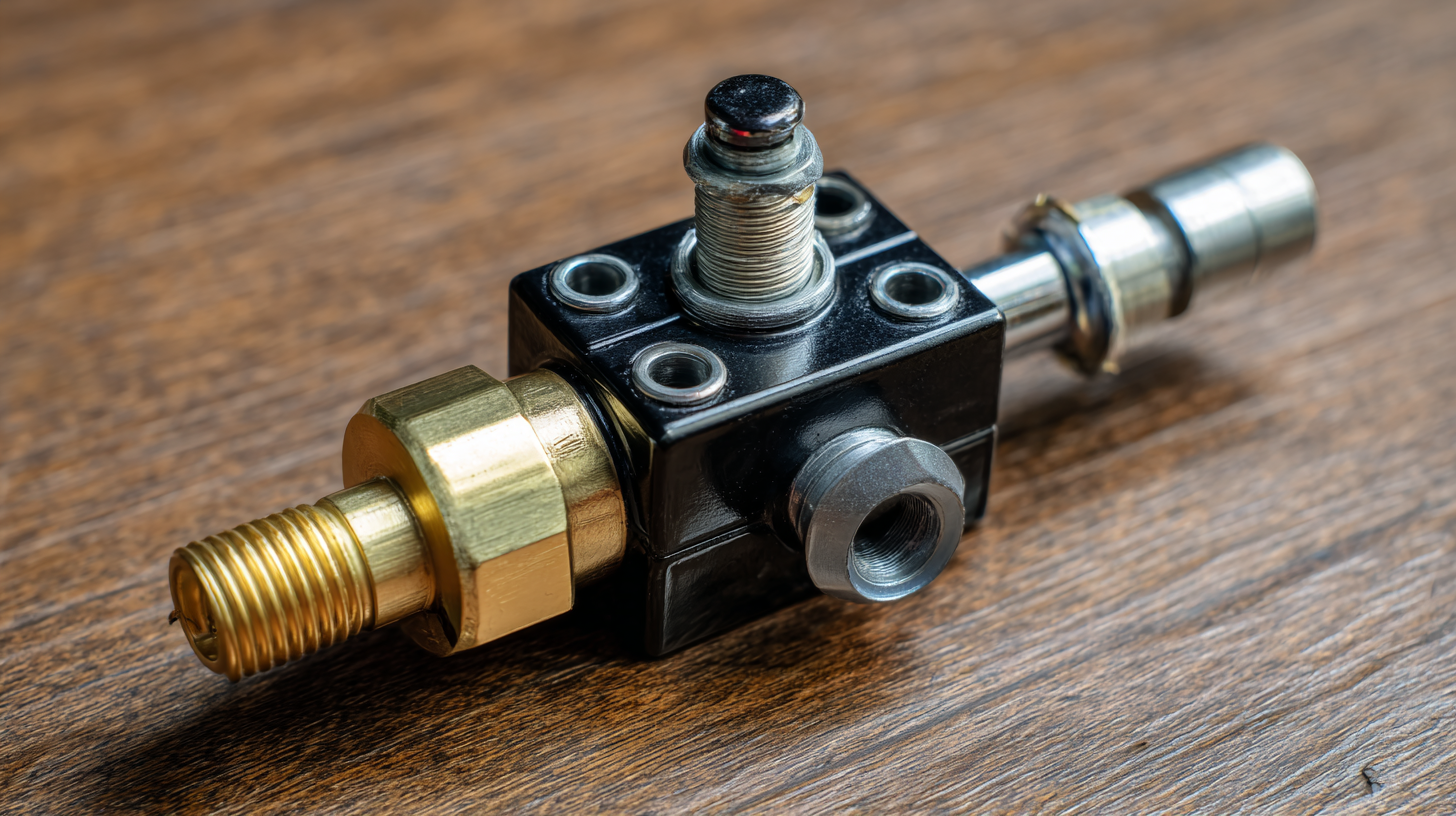

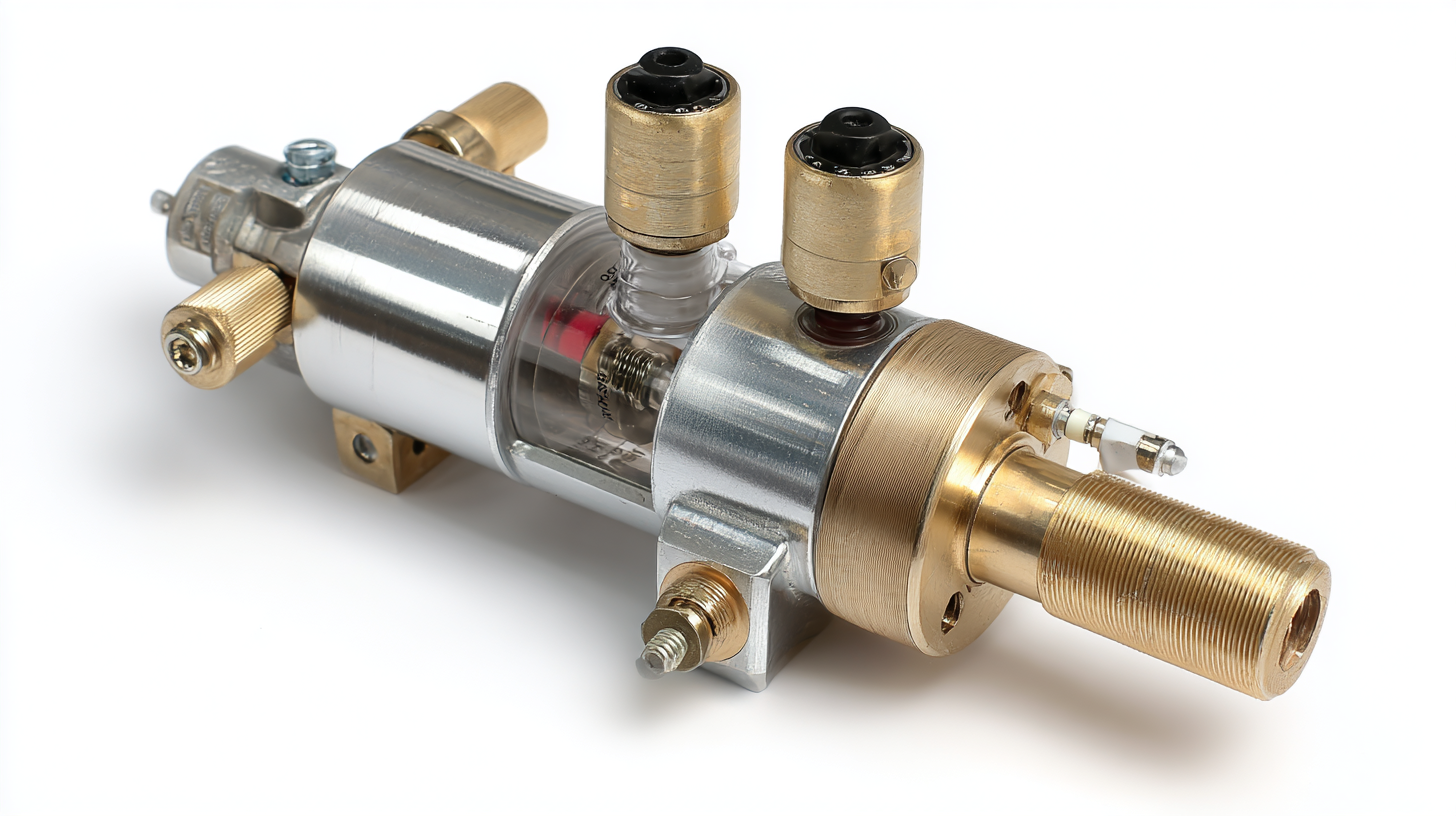

Hydraulic pressure regulators play a crucial role in ensuring the efficiency and safety of hydraulic systems. Understanding the key features and functions of these devices is essential for selecting the right one for your specific needs. At the core of any hydraulic pressure regulator is its ability to maintain a consistent output pressure regardless of variations in input pressure or flow rate. This stability is vital for the protection of sensitive components in hydraulic machinery, which could be damaged by pressure fluctuations.

Additionally, hydraulic pressure regulators come with various adjustments and features that cater to different operational requirements. Some regulators include built-in pressure gauges for real-time monitoring, while others may offer remote adjustment capabilities for convenience. It's also important to consider the materials used in the construction, as they can affect the regulator's durability and compatibility with various hydraulic fluids. By recognizing these key aspects, you can make an informed choice that enhances the performance and reliability of your hydraulic systems.

Choosing the Right Pressure Range for Your Applications

When selecting a hydraulic pressure regulator, one of the most critical parameters to consider is the pressure range. According to industry standards, the optimal pressure range can significantly influence the efficiency and safety of your hydraulic applications. For instance, the American National Standards Institute (ANSI) recommends that regulators be chosen based on a pressure range that closely aligns with the specific requirements of the machinery and processes involved. This ensures both performance and longevity, preventing potential system failures or unnecessary maintenance costs.

Tips: Always assess the operational environment and the specific demands of your equipment when determining the needed pressure range. For example, if you're operating in high-demand scenarios, such as in heavy industrial machinery, targeting a higher pressure range may be necessary.

Moreover, research from the Hydraulics & Pneumatics magazine indicates that improper pressure settings can lead to performance losses of up to 30%. Hence, selecting a regulator that accurately maintains the desired pressure can optimize system functionality. It is essential to consider not only the maximum operating pressure but also the minimum pressure to avoid cavitation and ensure smooth operation.

Tips: It may be beneficial to consult with a hydraulic engineer when defining your pressure needs to align the regulator with your application’s peak and low requirements. This collaboration can facilitate better long-term outcomes and system reliability.

Ultimate Guide to Choosing the Best Hydraulic Pressure Regulator for Your Needs

| Application | Pressure Range (psi) | Regulator Type | Flow Capacity (GPM) | Body Material |

|---|---|---|---|---|

| Hydraulic Press | 0-3000 | Direct-acting | 10 | Aluminum |

| Construction Equipment | 0-4000 | Balanced piston | 15 | Carbon Steel |

| Agricultural Machinery | 0-2500 | Diaphragm | 20 | Stainless Steel |

| Robotics | 0-1500 | Electronic | 5 | Plastic |

| Mobile Equipment | 0-2000 | Spring-loaded | 12 | Cast Iron |

Material Selection: Ensuring Durability and Performance

When selecting a hydraulic pressure regulator, material selection is crucial for ensuring both durability and performance. The most commonly used materials in manufacturing these devices include stainless steel, aluminum, and various polymers. According to a report by the Hydraulic Institute, stainless steel provides excellent corrosion resistance, making it ideal for applications involving harsh environmental conditions. Over 60% of industrial hydraulic systems employ stainless steel components, underscoring its reliability in maintaining system integrity under pressure.

Moreover, the choice of material can significantly impact the regulator's performance under varying pressures and temperatures. For instance, aluminum offers a lightweight option that can reduce overall system weight while maintaining acceptable performance levels for moderate pressure applications. Studies indicate that aluminum hydraulic regulators can withstand pressures up to 3000 PSI, making them suitable for both mobile and stationary equipment. However, for high-pressure applications, it's essential to choose materials that can consistently handle stress without compromising safety, which is why many engineers favor advanced polymers for specific applications, as they can provide lower friction and enhanced thermal stability.

Comparative Analysis of Hydraulic Pressure Regulators in the Market

When selecting a hydraulic pressure regulator, it's crucial to consider various factors that differentiate the models available on the market. According to a recent report from Research and Markets, the global hydraulic pressure regulator market is projected to grow at a CAGR of 6.5% until 2027, driven by the increasing demand for automation in industrial applications. A comparative analysis reveals that not all regulators are created equal; variations in flow rates, pressure ranges, and material construction can significantly impact performance. For instance, standard models typically operate at a maximum pressure of around 3000 PSI, while high-performance regulators can withstand pressures exceeding 5000 PSI, making them suitable for more demanding applications.

In addition to pressure ratings, the choice of materials is vital for durability and reliability. A study from the American Society of Mechanical Engineers found that regulators made from stainless steel offer superior resistance to corrosion, which is particularly important in hydraulic systems exposed to harsh environments. Furthermore, the integration of advanced technologies, such as electronic pressure sensing, is becoming increasingly prevalent. These innovations not only enhance precision but also contribute to overall system efficiency, reducing energy consumption by up to 20%. Thus, when assessing hydraulic pressure regulators, it is essential to weigh these critical aspects to identify the best fit for your specific operational needs.

Maintenance Tips for Prolonging the Life of Your Hydraulic Regulator

Hydraulic pressure regulators are essential components in hydraulic systems, ensuring consistent pressure and flow. To maximize their lifespan, proper maintenance is crucial. According to the International Fluid Power Society, the average lifespan of a hydraulic regulator can be significantly extended—by up to 30%—with routine checks and timely maintenance. Regular inspection of seals and connections can prevent leaks, while cleaning or replacing filters ensures the system operates efficiently.

Additionally, monitoring operating conditions is vital. A study by the National Fluid Power Association highlighted that over 70% of hydraulic system failures are linked to contamination and overheating. By implementing a regular maintenance schedule that includes checking fluid quality and temperature, operators can identify issues before they lead to costly breakdowns. Furthermore, using high-quality hydraulic fluids, as suggested by ISO standards, can enhance overall performance and durability, thereby prolonging the life of hydraulic regulators.