How to Effectively Choose the Right Pressure Regulator for Your Industrial Needs

In today's industrial landscape, the efficient management of pressure systems is critical for operational safety and productivity. A key component in this endeavor is the Pressure Regulator, which controls the pressure of gases and liquids, ensuring consistent performance across various applications. According to a report by MarketsandMarkets, the global pressure regulator market is expected to grow to USD 3.89 billion by 2025, highlighting the increasing reliance on these devices within industries such as oil and gas, pharmaceuticals, and manufacturing. Choosing the right Pressure Regulator is essential not just for maintaining system integrity but also for optimizing energy consumption and reducing operational costs. With numerous options available, understanding the specific requirements of your application, including pressure ranges and media compatibility, is crucial for making an informed decision that meets your industrial needs effectively.

Understanding the Specific Requirements of Your Industrial Application

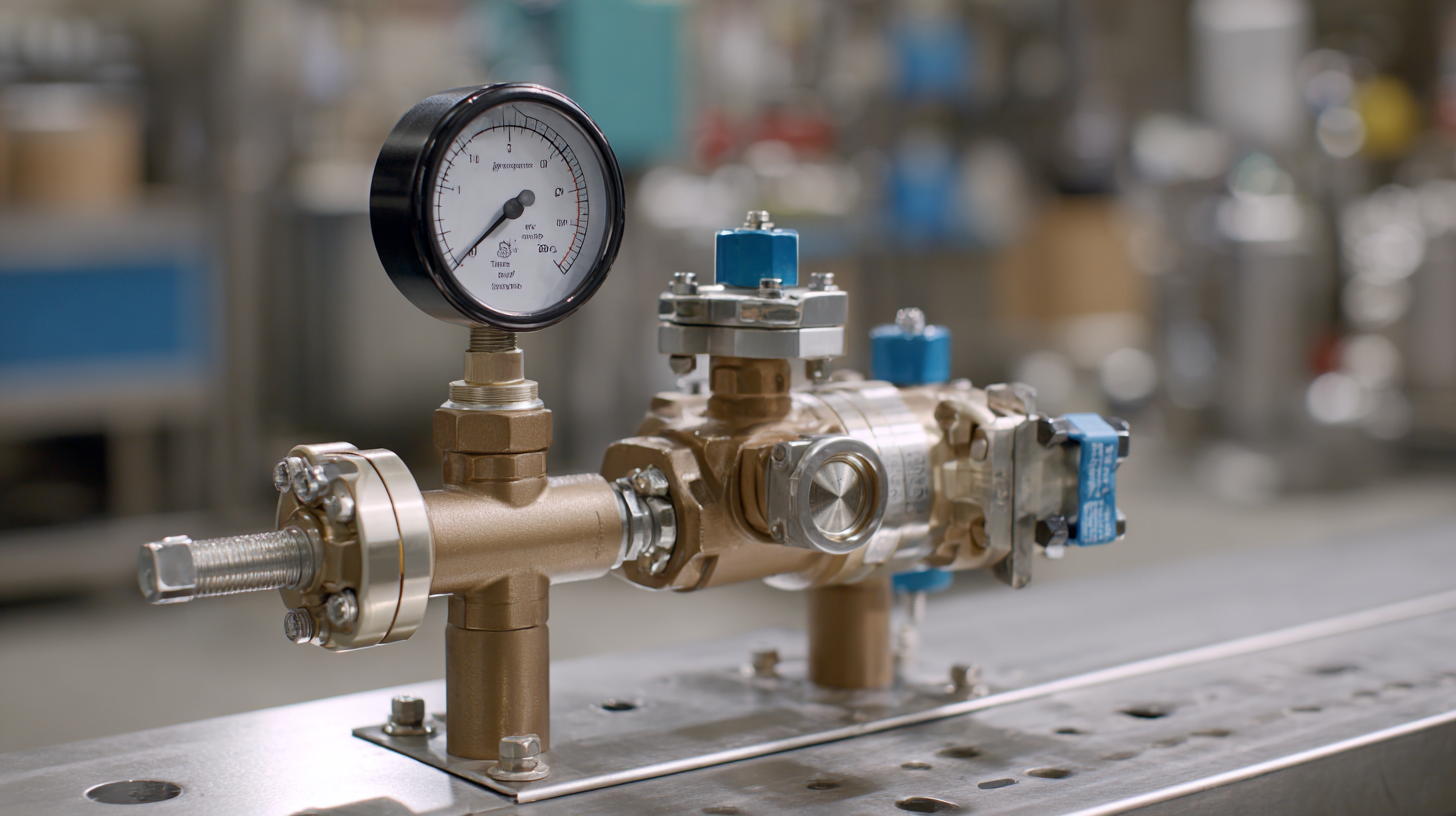

Choosing the right pressure regulator for your industrial needs begins with a thorough understanding of the specific requirements of your application. Different industries and processes demand distinct pressure levels and flow rates, so it is crucial to first assess the operational conditions. Factors such as the type of gas or liquid being regulated, the required pressure range, and the environmental conditions must be carefully evaluated.

Additionally, consider the compatibility of materials used in the regulator with the substances it will control. For example, certain chemicals may require regulators made from specific alloys or plastics to avoid corrosion and ensure safety. Furthermore, the installation environment should be taken into account—if the regulator will be used in extreme temperatures or under high vibration, selecting a robust design is essential. By aligning the regulator's specifications with the unique demands of your application, you can optimize performance and enhance the reliability of your industrial processes.

How to Effectively Choose the Right Pressure Regulator for Your Industrial Needs

| Application Type | Pressure Range (psi) | Flow Rate (SCFM) | Material Compatibility | Regulator Type |

|---|---|---|---|---|

| Hydraulic Systems | 1000 - 3000 | 10 | Steel, Aluminum | Pilot-Operated |

| Chemical Processing | 500 - 1500 | 5 | PVC, PTFE | Diaphragm |

| Gas Distribution | 200 - 600 | 15 | Brass, Stainless Steel | Spring-Loaded |

| Water Treatment | 10 - 50 | 8 | Bronze, Polypropylene | Pneumatic |

| Oil & Gas | 1500 - 6000 | 20 | Carbon Steel, Alloy | Heavy-Duty |

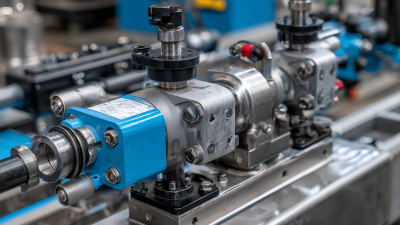

Evaluating Different Types of Pressure Regulators Available

When it comes to choosing the right pressure regulator for industrial applications, understanding the different types available is crucial. Pressure regulators can be classified into various categories such as spring-loaded, dome-loaded, and electronic regulators, each designed to meet specific operational needs.

Spring-loaded regulators are common due to their simplicity and reliability, making them suitable for many traditional applications. Dome-loaded regulators offer enhanced precision in pressure control, ideal for processes requiring exact pressure levels. Electronic regulators, on the other hand, provide advanced features and flexibility, allowing for automated adjustments based on real-time data.

Evaluating these options should involve an assessment of the application requirements, including the desired pressure range, flow rate, and the nature of the gases or liquids being regulated. Additionally, factors such as environmental conditions and maintenance needs should be considered.

For instance, in harsh environments, a regulator that can withstand fluctuations and contamination may be essential. By carefully analyzing these factors, industries can choose a pressure regulator that not only fits their needs but also ensures the efficiency and safety of their operations.

Key Factors to Consider: Flow Rate, Pressure Range, and Accuracy

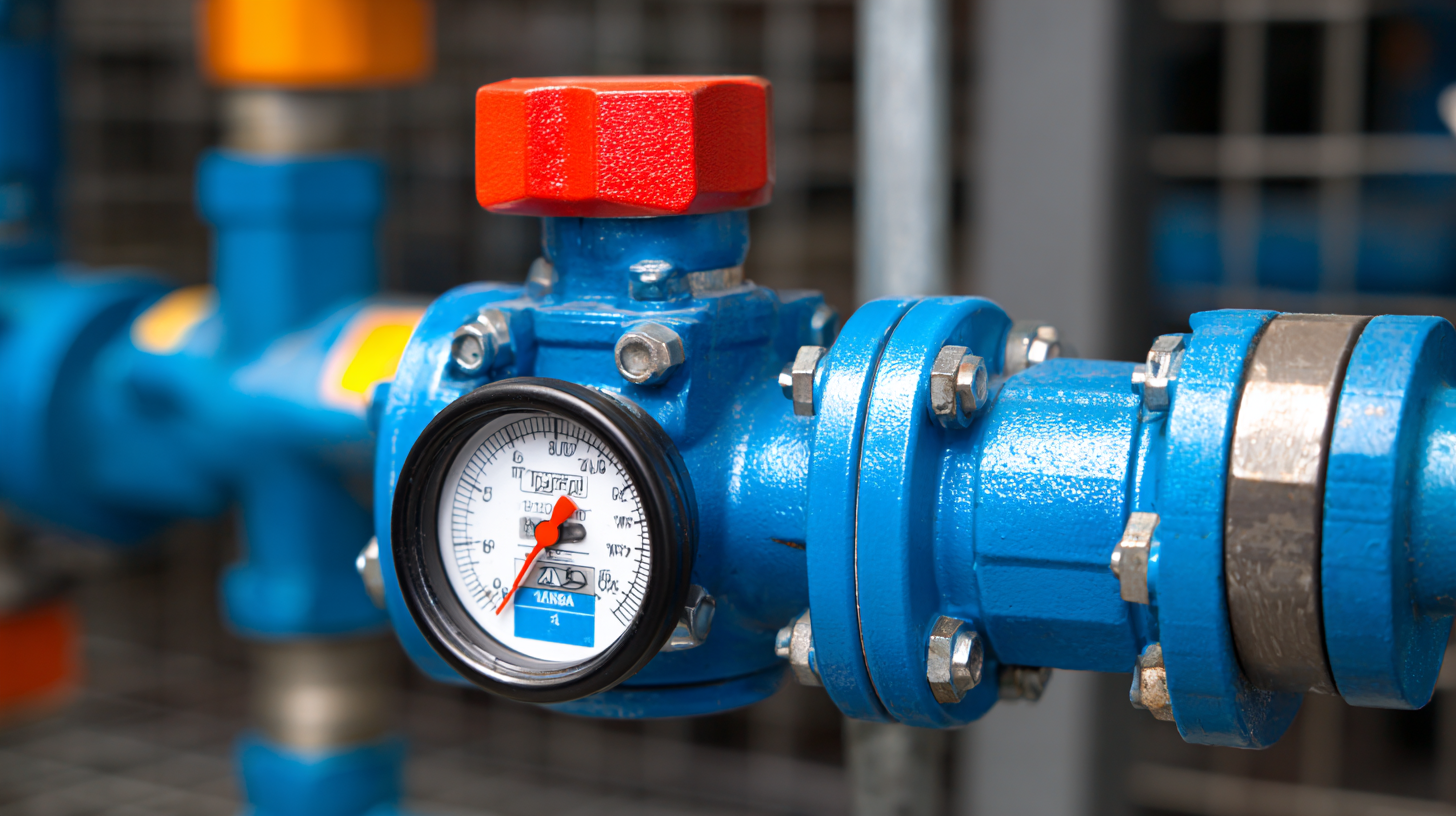

When selecting the right pressure regulator for industrial applications, three critical factors must be evaluated: flow rate, pressure range, and accuracy. The flow rate is paramount, as it dictates the volume of fluid or gas that can be processed effectively. According to an industry report by the National Institute of Standards and Technology, optimizing flow rate can enhance system efficiency by up to 20%, significantly impacting productivity and operational costs.

The pressure range is another essential consideration, as it determines the ability of the regulator to maintain a steady output pressure despite fluctuations in input pressure. A study from the American Society of Mechanical Engineers indicates that selecting a regulator with the appropriate pressure range can prevent equipment damage and ensure safety in operations. For instance, a regulator designed for a high-pressure application provides a far superior safety margin in environments where unexpected surges may occur.

Lastly, accuracy is crucial for maintaining process integrity, particularly in sectors like pharmaceuticals or fine chemical manufacturing. Research published in the Journal of Industrial Technology highlights that regulators with ±1% accuracy can dramatically improve product consistency, leading to reduced waste and compliance with stringent regulatory standards. By prioritizing these key factors, industrial operations can optimize performance and reliability in their pressure management systems.

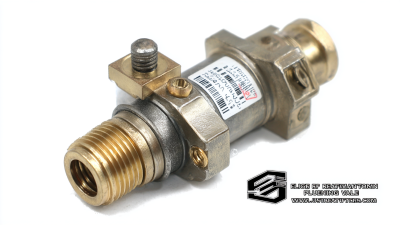

Assessing Material Compatibility for Longevity and Safety

When selecting a pressure regulator for industrial applications, assessing material compatibility is crucial for ensuring longevity and safety. According to a report by the American Society for Testing and Materials (ASTM), materials such as stainless steel, brass, and certain plastics like PEEK are commonly used in pressure regulators due to their resistance to corrosion and wear. The choice of material becomes even more significant when working with aggressive gases or fluids, as improper selection can lead to premature failure and safety hazards. For instance, a study published in the Journal of Materials Science highlights that pressure regulators made from unsuitable materials experienced a failure rate of up to 30% within the first year of use in corrosive environments.

Moreover, understanding the specific operational conditions can further inform material compatibility. Factors such as temperature, pressure, and the nature of the fluid or gas being regulated can dramatically influence the performance and durability of a pressure regulator. The Chemical Resistance Chart from the Plastics Industry Association indicates that while certain plastics are ideal for low-pressure applications, high-pressure environments may necessitate the use of metals. This understanding is essential for engineers and procurement specialists to ensure that the selected regulators not only meet regulatory standards but also provide reliable service throughout their intended lifespan.

Budgeting and Maintenance: Balancing Cost and Quality in Selection

When selecting the right pressure regulator for industrial applications, balancing cost and quality is paramount. According to a recent industry report, the average cost of pressure regulators can vary significantly based on type and specifications, ranging from a few hundred to several thousand dollars. Companies must take into consideration not only the initial purchase price but also the long-term maintenance costs associated with different models. Regular servicing can add an estimated 15-20% to the overall cost over the equipment's lifespan, emphasizing the importance of investing in quality to reduce future expenditures.

Budgeting effectively requires a thorough understanding of both upfront costs and ongoing maintenance needs. Industry analysts suggest creating a detailed budget that accounts for these variables, ensuring that companies can maintain operational efficiency without sacrificing safety or reliability. Leveraging value engineering concepts can aid in identifying cost-effective solutions without compromising on quality, tailoring choices to specific industrial needs while adhering to financial constraints. This strategic approach allows businesses to optimize their investments, ultimately leading to improved performance and sustainability in the long run.

Related Posts

-

Discover Elite Manufacturing from a Leading Chinese Factory: Your Source for the Best Pressure Reducing Valve

-

Navigating Global Trade Certification for Best Hydraulic Pressure Reducing Valve Procurement

-

Unlocking Efficiency with Natural Gas Regulators Benefits for Modern Industry

-

Leading Hydraulic Pressure Regulator Manufacturers from China at the 137th Canton Fair

-

Championing Excellence in China The Best Steam Pressure Reducing Valve Export Leader

-

7 Essential Benefits of Using a Low Pressure Regulator for Your Operations