What is a Damper Actuator and How Does It Work?

A Damper Actuator is a crucial component in HVAC systems. It controls airflow in ducts and terminals. These devices help maintain comfortable temperatures indoors. By adjusting damper blades, the actuator regulates air distribution.

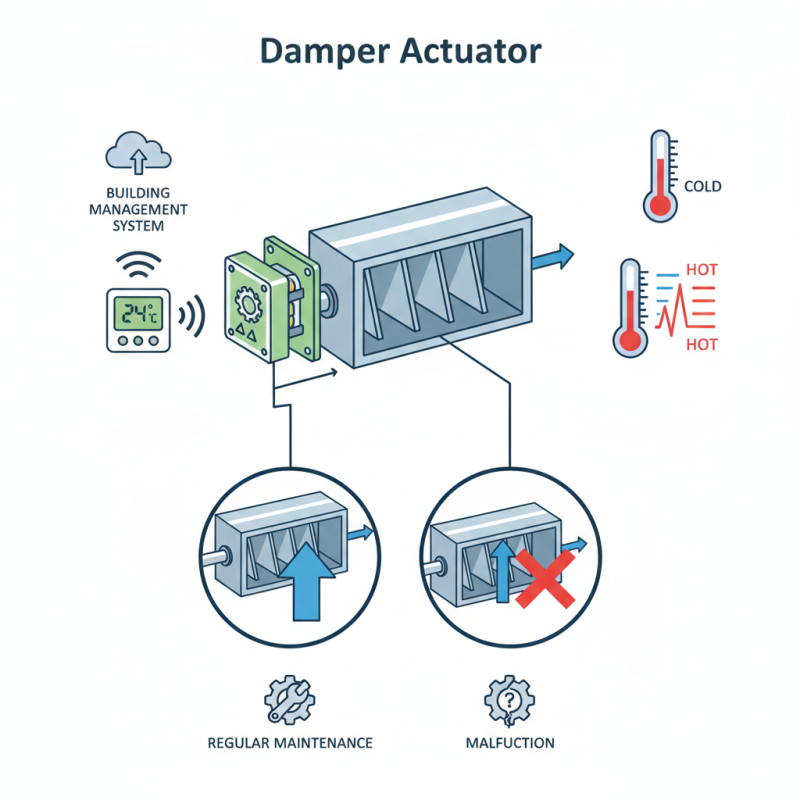

Understanding how a Damper Actuator works is essential for efficient system performance. It receives signals from thermostats or building management systems. When temperatures change, the actuator responds. It can open or close dampers to balance airflow. This process seems simple, yet it requires precise execution.

Sometimes, these actuators can malfunction. A stuck damper leads to uneven heating or cooling. Regular maintenance can help prevent such issues. However, even with care, problems may still arise. Ultimately, learning about a Damper Actuator enhances our understanding of environmental control.

Introduction to Damper Actuators

Damper actuators play a crucial role in various HVAC systems. These devices control the flow of air in ducts. They adjust dampers, which are panels that regulate airflow. An efficient damper actuator can improve energy efficiency. However, not all actuators are designed equally. Some may fail under high-stress conditions.

Understanding how damper actuators work can enhance their application. Most actuators are operated electronically or pneumatically. When electrical signals are sent, the actuator moves. It opens or closes the damper depending on the system's demands. This helps maintain optimal temperature and air quality. Yet, mechanical failures might occur. Regular maintenance is needed here.

A common issue is the delay in response time. Some actuators might lag, leading to inefficient airflow. It’s vital to monitor their performance regularly. Small adjustments can prevent larger problems down the line. Therefore, consider integrating control systems that track their operation. This can ensure swift air control and better system management.

Types of Damper Actuators

Damper actuators play a vital role in HVAC systems. They control airflow by adjusting dampers based on signals from controllers. There are several types of damper actuators, each serving specific applications.

Electric damper actuators are the most common. They use electric motors to open or close dampers. These actuators are efficient and provide precise control. But they may fail under certain conditions if not properly maintained.

Pneumatic damper actuators work with air pressure. They are durable and suitable for harsh environments, but might be less responsive.

Another type is the hydraulic damper actuator. These actuators use liquid to operate dampers. They can handle larger dampers but require a dedicated hydraulic system. Typically, they are costlier than electric types. Each type has advantages and limitations. Choosing the right actuator is crucial for optimal system performance.

How Damper Actuators Function

Damper actuators play a vital role in HVAC systems. They control airflow in ventilation systems by automatically opening and closing dampers. These devices respond to changes in temperature and pressure. When the thermostat signals for heating or cooling, the actuator adjusts the damper position. This ensures optimal air distribution throughout the building.

The mechanics behind damper actuators can vary. Some use electric motors, while others rely on pneumatic or hydraulic systems. Electric actuators are often more efficient but can complicate installations. Pneumatic systems are simpler but require air pressure maintenance. It’s interesting that not every system is perfect; each type has pros and cons that should be considered.

Installation can also pose challenges. Space constraints may limit access to dampers. It might be necessary to conduct regular maintenance checks. Without these, actuator performance can decline. Additionally, users sometimes overlook the importance of proper calibration. Accurate settings are crucial for effective HVAC operation. Understanding these nuances can help in optimizing performance and efficiency.

Applications of Damper Actuators

Damper actuators play a crucial role in various applications. In HVAC systems, they regulate airflow. These devices can open or close dampers, controlling temperature and ventilation. Proper airflow enhances comfort and energy efficiency.

In industrial settings, damper actuators manage emissions. They help in controlling exhaust flow. This ensures that pollutants are minimized before they enter the atmosphere. Their precision is vital to meeting regulatory standards.

Though effective, damper actuators can sometimes malfunction. A lack of maintenance may cause issues. Periodic checks can prevent undesirable situations. Users must stay vigilant and attentive. Regular adjustments keep systems running smoothly.

Damper Actuator Applications

Benefits of Using Damper Actuators

Damper actuators play a crucial role in controlling airflow in HVAC systems. They adjust the position of dampers to regulate ventilation. This helps maintain a comfortable indoor environment. Using damper actuators can greatly enhance energy efficiency in buildings. When airflow is optimized, heating and cooling systems work more effectively. This means lower energy bills for users over time.

Another advantage is the ability to improve air quality. By controlling fresh air intake, dampers can help balance indoor air. It prevents stale air from accumulating. However, reliance on these devices comes with challenges. For instance, improper calibration can lead to inefficiencies. Regular maintenance is necessary to ensure optimal performance.

Moreover, damper actuators allow for zoning in larger buildings. This means different areas can have unique temperature settings. Flexibility in climate control is beneficial for comfort. Still, the complexity of setups may require professional input. Understanding the limitations of technological systems is vital. Without careful oversight, the benefits might not be fully realized.