Unlocking Efficiency with Natural Gas Regulators Benefits for Modern Industry

In today's fast-paced industrial landscape, efficiency is more crucial than ever, and Natural Gas Regulators play a pivotal role in achieving that goal. As businesses seek to optimize their operations and reduce costs, the benefits of implementing advanced natural gas regulation systems become increasingly apparent. These regulators not only ensure the safe and efficient delivery of natural gas but also enhance overall operational performance by maintaining consistent pressure, minimizing waste, and improving energy management. In this blog, we will explore the various advantages that Natural Gas Regulators can bring to modern industry, highlighting how they contribute to streamlined processes, cost savings, and greater sustainability in energy consumption. Join us as we delve into the essential functions of these devices and their significant impact on industrial efficiency.

Strategies for Integrating Natural Gas Regulators in Industrial Operations

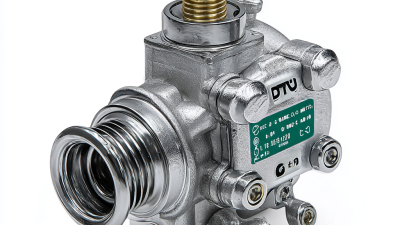

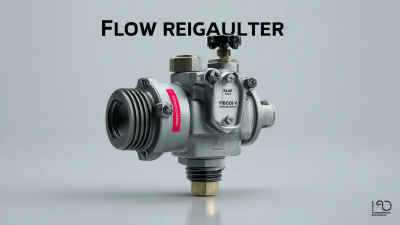

Integrating natural gas regulators into industrial operations can significantly enhance efficiency and safety in production processes. These regulators maintain optimal pressure levels, ensuring a consistent gas supply that is crucial for the functioning of various machinery and heating systems. Implementing advanced regulators allows industries to fine-tune their energy consumption, minimizing waste and reducing operational costs. Additionally, modern regulators equipped with smart technology can monitor performance in real-time, providing valuable data that can be leveraged for further optimization.

When considering strategies for integration, industries should start by conducting a thorough assessment of their current gas systems. Identifying areas where pressure fluctuations or leaks occur is essential. Next, incorporating advanced gas regulators that feature remote monitoring capabilities can enhance oversight and enable quick responses to potential issues. Training staff on the importance of maintaining and calibrating these systems is equally crucial, ensuring that all personnel understand how to maximize the equipment's capabilities. As industries embrace these strategies, they not only unlock greater efficiency but also contribute to sustainable practices in energy use.

Maximizing Cost Savings Through Efficient Natural Gas Regulation

In today's competitive industrial landscape, maximizing cost savings is essential for sustaining growth and profitability. Efficient natural gas regulation plays a pivotal role in this pursuit, allowing industries to harness the power of one of the cleanest and most cost-effective energy sources available. By implementing advanced natural gas regulators, companies can optimize their energy consumption, reduce operational costs, and enhance overall efficiency. These regulators ensure precise control over gas flow, thereby minimizing waste and ensuring that facilities can operate at peak performance.

Moreover, the benefits extend beyond mere cost reductions. Improved energy regulation fosters a safer working environment, minimizing the risk of leaks or accidents associated with natural gas supply. Industries that adopt these advanced technologies are not only making a sound financial decision but are also contributing to environmental sustainability by lowering emissions associated with energy use. As businesses increasingly prioritize sustainable practices, efficient natural gas regulation stands out as a crucial component in their strategy to achieve both economic and ecological goals.

Enhancing Safety Protocols with Advanced Natural Gas Regulators

Natural gas regulators are pivotal in modern industrial applications, ensuring that gas is delivered safely and efficiently. Advanced natural gas regulators incorporate cutting-edge technology that significantly enhances safety protocols. According to a report from the American Gas Association, the implementation of advanced regulation systems can reduce safety incidents related to gas leaks by up to 30%. These systems are designed with precision-engineered components that allow for real-time monitoring and adjustment of gas pressure, minimizing the risk of over-pressurization which can lead to hazardous situations.

Moreover, the evolution of smart natural gas regulators is transforming safety measures in the industry. These devices are equipped with sensors that detect anomalies, sending alerts to operators instantly. A study by the International Energy Agency found that employing sensor-integrated regulators can improve response times to potential gas leaks by 40%, thereby mitigating risks before they escalate into serious incidents. By investing in advanced natural gas regulation technologies, industries are not only enhancing their safety protocols but also ensuring compliance with stringent regulatory standards, thus safeguarding their operations and workforce.

Case Studies: Success Stories of Natural Gas Implementation in Industry

Natural gas has emerged as a key player in driving efficiency across various industries, exemplified by numerous case studies that highlight its transformative impact. For instance, a study from the U.S. Department of Energy indicates that facilities switching to natural gas can achieve energy cost savings of up to 30% compared to those relying solely on traditional fuels. Such significant savings are particularly critical for manufacturing industries, where operational margins are often thin.

One notable example is the American steel manufacturing sector, which has increasingly adopted natural gas technologies. According to the American Iron and Steel Institute, the shift has led to a 15% reduction in energy consumption per ton of steel produced over the past decade. Moreover, companies like Nucor Corporation have reaped the benefits of using natural gas in electric arc furnaces, resulting in a decrease in carbon emissions by approximately 20% per ton of steel, showcasing both economic and environmental advantages. These success stories underscore the substantial role natural gas regulators play in enabling industries to operate more efficiently while fostering sustainability.

Future Trends in Natural Gas Regulation and Industrial Efficiency

As industries continue to evolve, the importance of natural gas regulation becomes increasingly evident. The future trends in this sector highlight the critical role of effective leak detection and mitigation strategies. In 2023, the leak containment market was valued at $868.05 million, showcasing a stable growth trajectory driven by stringent environmental regulations and heightened awareness of safety measures across various industries. This trend is indicative of a broader commitment to sustainability and operational efficiency, as businesses seek to comply with regulations while optimizing their processes.

Moreover, specialized products like PTFE-lined ball valves are becoming essential in modern industrial applications, with a forecasted market value of $64.14 million in 2024, projected to grow to $84.01 million by 2032. This represents a growth rate of 3.4% and underscores the emphasis on materials that enhance reliability and reduce environmental risks. The demand for such innovations reflects a growing recognition of the need for efficiency and safety in the handling of natural gas and other utilities. As industries pivot towards greener practices, the integration of advanced technologies and materials within natural gas regulation will undoubtedly play a key role in shaping a more efficient industrial landscape in the years to come.

Unlocking Efficiency with Natural Gas Regulators: Benefits for Modern Industry - Future Trends in Natural Gas Regulation and Industrial Efficiency

| Dimension | Current Value | Future Projection | Impact on Industry Efficiency |

|---|---|---|---|

| Natural Gas Consumption (Billion Cubic Feet) | 29,000 | 35,000 | +20% |

| Number of Natural Gas Regulators | 250,000 | 300,000 | Increased capacity |

| CO2 Emissions Reduction (%) | 30% | 40% | +33% efficiency |

| Operational Cost Savings (%) | 15% | 25% | Improved profitability |

| Investment in Technology ($ Billion) | 5 | 10 | Technology advancement |

Related Posts

-

Hydraulic Pressure Regulator Innovations Highlighted at Canton Fair 2025 with Record International Buyer Attendance

-

Finding the Perfect Supplier for Best Pneumatic Control Valves Your Comprehensive Guide

-

Navigating Global Standards: The Impact of Import and Export Certifications on Best Flow Regulator Valve Supply Chains

-

Unveiling the Best High Pressure Regulator Options for Global Buyers

-

Unmatched Innovation in Best Air Flow Control Valves from China's Leading Manufacturing Plants

-

Discover the Excellence of China's Leading Manufacturer: The Best Air Flow Control Valve