Discover Elite Manufacturing from a Leading Chinese Factory: Your Source for the Best Pressure Reducing Valve

In today's industrial landscape, the importance of efficient pressure management cannot be overstated, particularly in the manufacturing sector. Pressure reducing valves (PRVs) play a crucial role in ensuring optimal performance and safety across various applications, including water distribution, chemical processing, and HVAC systems. According to a report by MarketsandMarkets, the global pressure valve market is projected to reach USD 4.63 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.1%. This growth underscores the increasing demand for advanced PRV technologies that enhance operational efficiency and reduce risks associated with pressure fluctuations.

As a leading Chinese factory specializing in the production of high-quality pressure reducing valves, we are committed to delivering innovative solutions that cater to the evolving demands of the industry, ultimately helping our clients achieve superior performance and reliability.

Exploring the Excellence of Chinese Manufacturing in Pressure Reducing Valves

The excellence of Chinese manufacturing in pressure reducing valves is evidenced by the increasing demand for high-quality, reliable solutions in various global industries. According to recent reports, the solenoid valve market is projected to witness significant growth, driven by industrial automation and the need for efficient fluid control systems. China, as a leading manufacturer, plays a crucial role in this expansion, delivering advanced engineering capabilities and technologies that meet international standards.

Moreover, companies like Trillium Flow Technologies are exemplifying this trend by integrating innovative technologies into their products aimed at sectors such as water, energy, and oil and gas. This synergy of cutting-edge engineering and manufacturing expertise positions Chinese factories as vital contributors to the global pressure control solutions landscape. As these industries evolve, the focus on operational efficiency and safety remains paramount, reinforcing the importance of high-performing pressure reducing valves. With their commitment to excellence, Chinese manufacturers are well-equipped to fulfill the growing needs of markets worldwide, ensuring unmatched performance in pressure management applications.

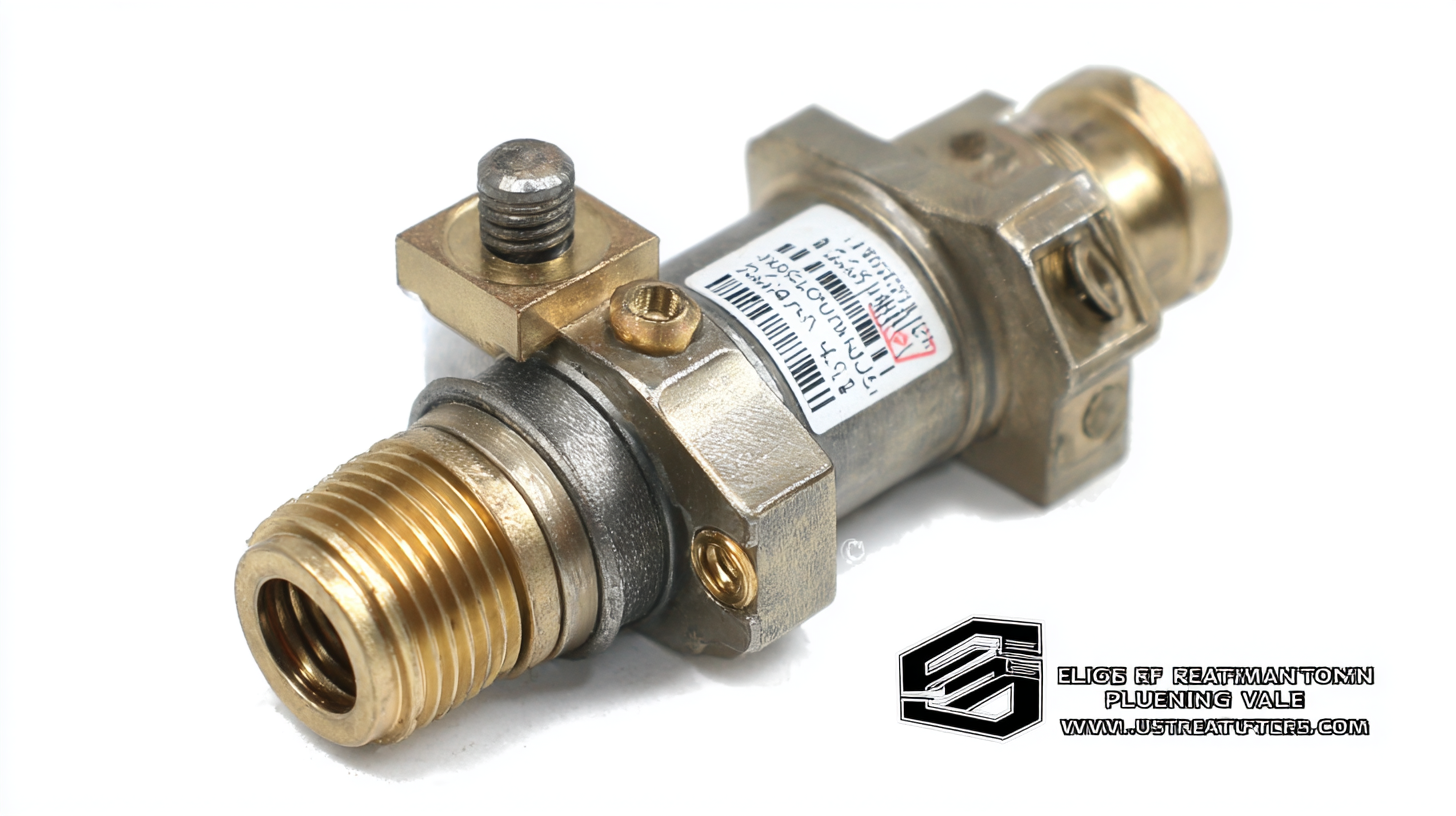

The Unique Features of Pressure Reducing Valves from Leading Chinese Factories

When it comes to pressure reducing valves, leading Chinese factories have set the benchmark for innovation and quality in manufacturing. These valves are engineered to maintain consistent pressure levels within various systems, ensuring safety and efficiency. A standout feature of these valves is their advanced technology, allowing for precise pressure adjustments which cater to specific operational needs. This adaptability makes them ideal for diverse industries, from water treatment to oil and gas.

Another unique aspect of pressure reducing valves produced by top Chinese manufacturers is their robust construction. Typically made from high-grade materials, these valves are designed to withstand extreme conditions and corrosive environments. Additionally, many factories employ strict quality control measures and certifications, ensuring that each valve meets international standards. As a result, customers can rely on their durability and performance, making them an excellent investment for any project requiring reliable pressure regulation.

Quality Control Practices Ensuring Top-notch Production Standards in China

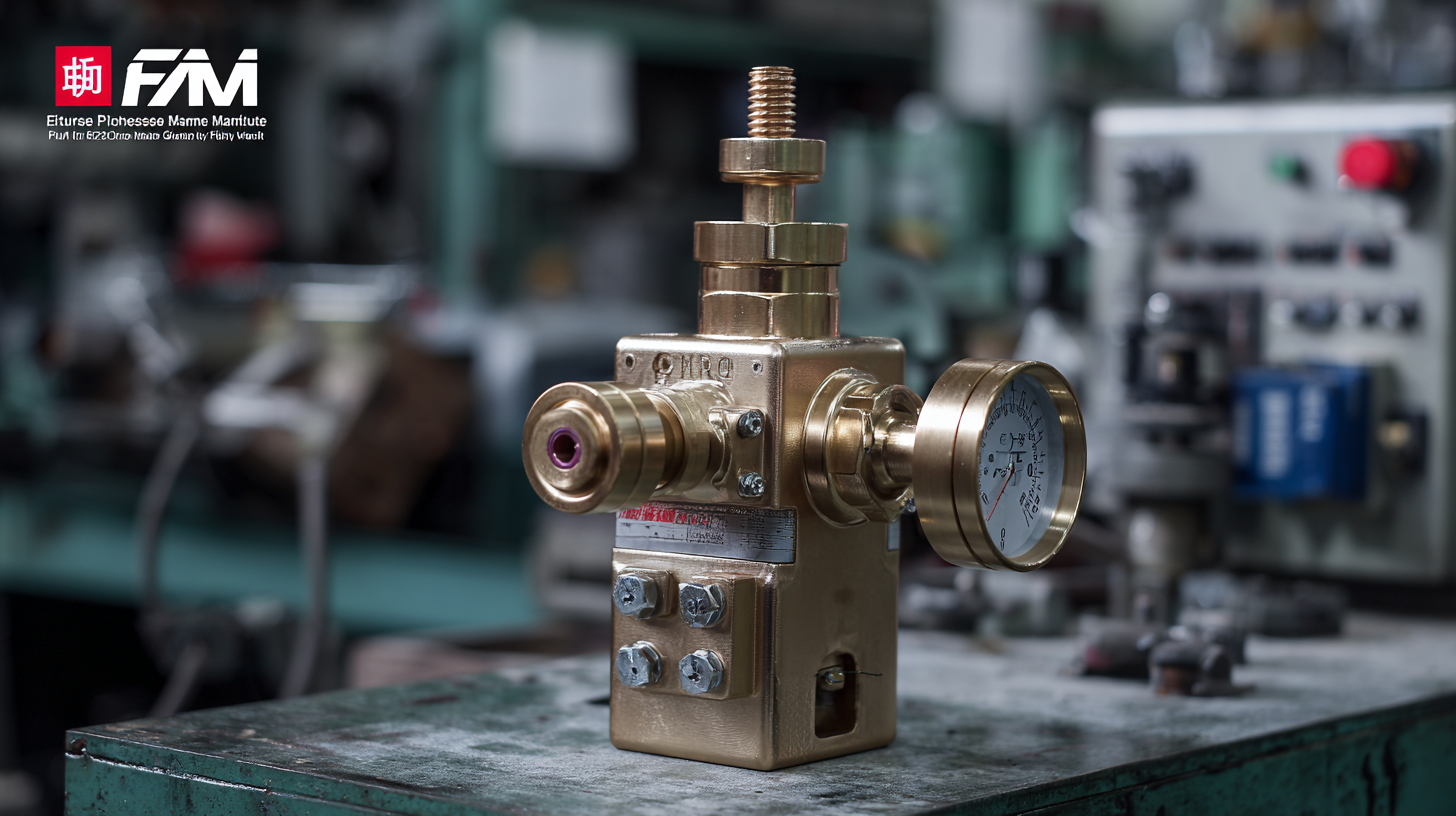

In the competitive landscape of manufacturing, quality control practices are paramount, especially in industries like valve production. According to a report by the International Organization for Standardization (ISO), organizations that implement comprehensive quality management systems can achieve a 30% reduction in operational costs while increasing production efficiency by as much as 20%. In China, leading factories employ rigorous quality control measures to ensure that each pressure reducing valve not only meets local standards but also international specifications.

Advanced testing protocols are a cornerstone of these quality control practices. For instance, factories often use automated testing equipment to assess the pressure performance and durability of valves, aligning with the guidelines set forth by the American Society of Mechanical Engineers (ASME). Reports indicate that manufacturers who adopt automation in their quality checks can enhance their defect detection rates by 50%, thereby producing products that consistently adhere to top-notch production standards. The focus on quality assurance in Chinese manufacturing not only elevates the trust in their products but also positions them as competitive players in the global market.

Pressure Reducing Valve Production Quality Control Metrics

This chart illustrates the quality control metrics for pressure reducing valve production in a leading Chinese factory. The metrics include defect rate, inspection pass rate, and customer satisfaction over the past year.

Innovative Technologies Revolutionizing the Pressure Reducing Valve Industry

The pressure reducing valve (PRV) industry is experiencing a significant transformation, largely driven by innovative technologies that are reshaping traditional manufacturing processes. With the rise of smart manufacturing, leading Chinese factories are adopting advanced automation and precision engineering techniques to produce high-quality PRVs that meet the demands of modern applications. Automation not only increases production efficiency but also enhances the reliability and consistency of valve performance, ensuring optimal functionality in critical systems.

Moreover, the integration of IoT (Internet of Things) technology within pressure reducing valves is paving the way for smarter solutions. These valves can now be equipped with sensors that monitor pressure levels in real time, providing feedback that allows for immediate adjustments and maintenance alerts. This proactive approach reduces downtime and improves system efficiency, leading to increased safety and reduced operational costs. As the industry embraces these innovations, manufacturers are not just producing valves; they are delivering comprehensive solutions that cater to the evolving needs of markets worldwide.

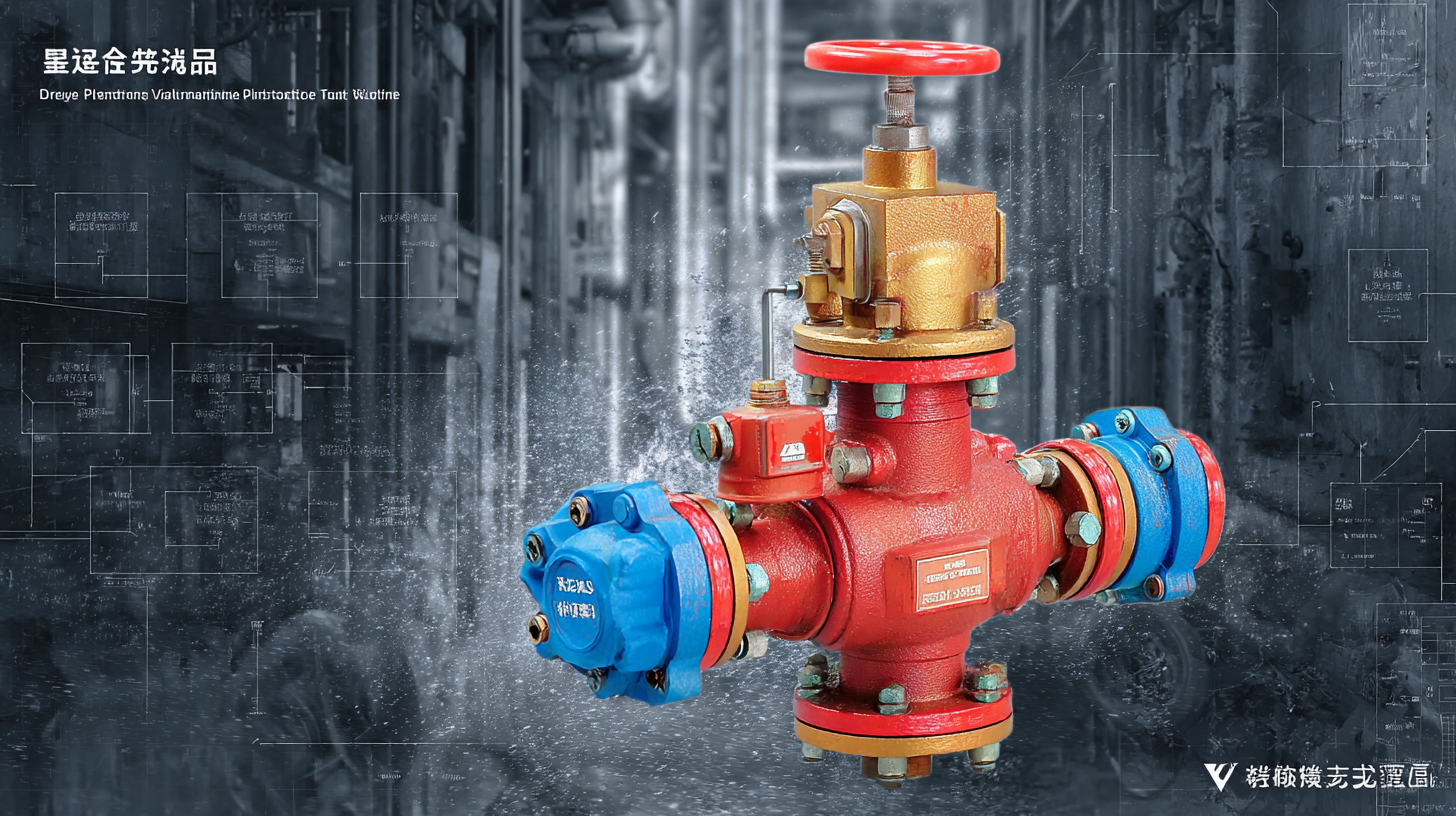

Global Impact of Chinese Pressure Reducing Valves on International Markets

The global market has witnessed a significant transformation with the rise of Chinese manufacturing, especially in the production of vital components like pressure reducing valves. These valves play a crucial role in numerous industries, including oil and gas, water supply, and HVAC systems. China's ability to produce high-quality valves at competitive prices has not only increased their availability but also influenced pricing strategies and product standards worldwide. As a result, global manufacturers are reevaluating their supply chains, often opting for Chinese suppliers to remain competitive.

Moreover, the impact of Chinese pressure reducing valves on international markets extends beyond just cost-effectiveness. Chinese factories are increasingly focusing on innovation and technology integration, resulting in advanced products that meet international certifications and standards. This shift enables global players to access cutting-edge technology without the burden of exorbitant costs. Consequently, the continuous evolution of Chinese manufacturing capabilities positions it as a pivotal factor in the global dynamics of pressure reducing valves, reshaping the industry's landscape and encouraging higher standards across the board.