7 Essential Benefits of Using a Low Pressure Regulator for Your Operations

In today's industrial landscape, the efficient management of pressure systems is paramount for enhancing operational performance and safety. Utilizing a Low Pressure Regulator can lead to significant operational benefits, as evidenced by recent studies indicating that optimizing pressure regulation can reduce energy consumption by up to 30% in manufacturing environments. A well-designed pressure regulation system not only ensures stable performance but also minimizes the risk of equipment damage and downtime.

Furthermore, the 2022 report by the International Energy Agency highlighted that implementing advanced pressure regulation technologies could result in a potential annual savings of billions for industries globally. Thus, understanding the essential benefits of incorporating a Low Pressure Regulator into your operations becomes crucial for achieving both economic and environmental sustainability.

Understanding Low Pressure Regulators and Their Importance

Low pressure regulators play a crucial role in various industrial operations by ensuring consistent and safe gas flow. Understanding their function can significantly enhance operational efficiency and safety. These devices maintain a reduced pressure downstream, which is vital for processes that require precise control over gas flow, such as in laboratories, manufacturing facilities, and healthcare applications. By effectively managing pressure levels, low pressure regulators help prevent equipment damage and reduce the risk of operational hazards associated with high-pressure gas systems.

Moreover, the importance of low pressure regulators extends beyond just safety; they also contribute to cost savings and energy efficiency. By ensuring that gas is used at optimal levels, these regulators minimize waste and facilitate smoother operations. This not only streamlines production processes but also leads to lower energy expenses, making operations more sustainable. As industries continue to prioritize efficiency and safety, understanding and implementing low pressure regulators can provide a significant competitive advantage.

Benefits of Using a Low Pressure Regulator

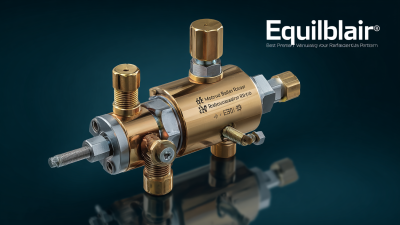

This bar chart illustrates the essential benefits of using a low pressure regulator in operations. The scores range from 1 to 10, reflecting the significance of each benefit such as efficiency, cost savings, and safety.

Enhanced Safety and Risk Mitigation in Operations

Using a low pressure regulator in your operations offers enhanced safety and risk mitigation, making it an indispensable asset in various industrial settings. By maintaining a consistent and reduced pressure, these regulators help prevent potential hazards associated with high-pressure systems, such as leaks and explosions. This controlled environment fosters a safer workspace for employees, minimizing the risk of accidents.

Tip: Regularly inspect and maintain your low pressure regulator to ensure optimal performance. Conducting routine checks can help identify any wear and tear that could compromise safety. Additionally, training your team on the proper usage and emergency procedures related to pressure equipment can significantly reduce risks.

Furthermore, low pressure regulators can improve operational efficiency by reducing the likelihood of system failures that often stem from pressure fluctuations. This stability not only protects your equipment but also ensures that production processes remain uninterrupted. The result is a more reliable system that supports both safety and productivity.

Tip: Implement a pressure monitoring system alongside your regulators to provide real-time data on pressure levels. This proactive measure allows for quick responses to any abnormal fluctuations, further enhancing safety protocols in your operations.

7 Essential Benefits of Using a Low Pressure Regulator for Your Operations - Enhanced Safety and Risk Mitigation in Operations

| Benefit | Description | Impact on Operations | Safety Improvement |

|---|---|---|---|

| Pressure Control | Ensures stable pressure output for various processes. | Reduces equipment wear and enhances efficiency. | Minimizes the risk of overpressure incidents. |

| Energy Efficiency | Optimizes the use of energy by maintaining appropriate pressure levels. | Reduces operational costs and energy consumption. | Leads to lower emissions and enhances safety compliance. |

| Leak Prevention | Reduces the chances of leaks in gas and liquid systems. | Enhances system reliability and integrity. | Significantly decreases explosion risks from leaking gases. |

| User-Friendly Design | Simple interfaces make regulation easy for operators. | Facilitates quick adjustments and troubleshooting. | Promotes safer operations by minimizing user errors. |

| Cost-Effectiveness | Long-lasting components lower replacement frequency. | Maximizes budget efficiency in operational setups. | Reduces cost of potential accidents through better safety controls. |

| Adaptability | Can be used in a variety of applications across different industries. | Supports diverse operational needs efficiently. | Improves safety standards in multiple contexts. |

| Regulatory Compliance | Helps meet industry regulations for pressure management. | Ensures operations remain lawful and audit-ready. | Mitigates the risk of legal penalties and shutdowns. |

Cost Efficiency: Lower Operational Costs with Low Pressure Regulators

When it comes to maximizing efficiency in operations, utilizing low pressure regulators can significantly contribute to cost savings. According to a recent report by the American Gas Association, businesses that implement low pressure systems observe an average reduction of 30% in their operational energy costs. This reduction is primarily due to the more efficient management of gas flow, which minimizes energy loss and maximizes utilization.

Furthermore, the use of low pressure regulators can enhance the lifespan of equipment, leading to additional savings. A study from the National Institute of Standards and Technology highlighted that maintaining lower pressure can effectively decrease wear and tear on machinery, reducing maintenance costs by approximately 25%. This not only lowers immediate operational expenses but also extends the service life of critical industrial components, resulting in a more sustainable approach to resource management. In this landscape of rising energy prices, adopting low pressure regulators becomes a strategic move for any business looking to stay competitive while controlling costs.

Improved Equipment Longevity Through Pressure Regulation

Improved equipment longevity through pressure regulation is a critical concern for various industries, particularly in sectors such as healthcare and manufacturing. Low pressure regulators play a pivotal role in maintaining optimal operational conditions, which directly contribute to the lifespan of equipment. For instance, recent studies in wastewater management have shown that excess pressure can lead to mechanical failures in treatment facilities, increasing downtime and repair costs. By utilizing low pressure regulators, industries can significantly reduce wear and tear on machinery, resulting in a potential decrease in maintenance costs by up to 30%, as reported by several industry analyses.

Moreover, in the context of renewable energy and medical device production, the integration of digital technologies has demonstrated that equipment designed to operate under regulated pressure can enhance both efficiency and performance. A systematic review on industrial processes highlights that equipment qualification testing in sectors like nuclear power plants showcases the benefits of maintaining consistent pressure levels, which can lead to a 20% improvement in operational reliability. This indicates that adopting low pressure regulation not only extends equipment life but also paves the way for safer and more sustainable operational practices in complex and high-stakes environments.

Versatility: Applications of Low Pressure Regulators in Various Industries

Low pressure regulators play a crucial role across various industries, ensuring precise pressure control and enhancing operational efficiency. In the manufacturing sector, these regulators are essential for processes involving gases such as natural gas, propane, or nitrogen. According to a recent report by Grand View Research, the global gas regulator market is expected to reach USD 2.3 billion by 2025, driven by the increasing demand for efficient and safe gas distribution systems. Low pressure regulators are particularly valued for their ability to maintain a consistent pressure, minimizing the risk of gas leaks and other safety hazards in production lines.

In the healthcare industry, low pressure regulators are indispensable for managing medical gases used in patient care. The American Hospital Association estimates that nearly 80% of all hospitals utilize some form of gas regulation technology. Precise regulation is vital for ensuring patient safety and maintaining the integrity of critical care environments. Furthermore, in the food and beverage sector, these regulators help control the carbonation levels in soft drinks and the gas flow for food preservation, enhancing product quality and extending shelf life. The versatility of low pressure regulators demonstrates their significance across multiple applications, ultimately contributing to improved safety and efficiency in diverse operational settings.

Related Posts

-

Maximizing Value: After-Sales Support and Maintenance Savings for the Best Low Pressure Regulators

-

Unveiling the Best High Pressure Regulator Options for Global Buyers

-

Hydraulic Pressure Regulator Innovations Highlighted at Canton Fair 2025 with Record International Buyer Attendance

-

Maximizing Value with Best Equilibar Back Pressure Regulator Through Superior After Sales Service and Low Repair Costs

-

Finding the Ideal Manufacturer for Best Pressure Reducing Valves in Your Industry

-

Exploring Diverse Alternatives for Optimal Performance of Best Pneumatic Control Valves