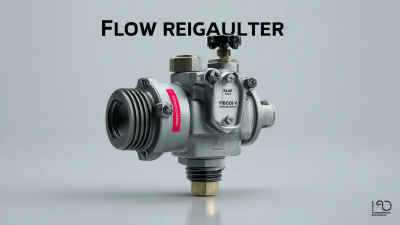

Understanding Issues Related to Flow Regulator Valve Performance and Efficiency

The performance and efficiency of a Flow Regulator Valve are critical components in various industrial applications, where maintaining a consistent flow rate can significantly impact overall system functionality. Understanding the intricacies of how these valves operate and the common issues that can arise is essential for engineers and technicians alike. In this blog, we will explore the fundamental aspects of Flow Regulator Valves, delving into the factors that influence their performance, potential problems that may affect their efficiency, and effective strategies to optimize their functionality. By gaining insights into these elements, readers will be better equipped to troubleshoot issues and implement solutions that enhance the reliability and effectiveness of their flow control systems. Whether you are looking to refine existing setups or are new to the world of flow regulation, this guide aims to provide valuable knowledge and practical tips for maximizing the performance of Flow Regulator Valves.

Key Factors Affecting Flow Regulator Valve Performance

The performance and efficiency of flow regulator valves are influenced by several key factors that contribute to their operational effectiveness in various applications. One primary factor is the design and material of the valve itself. High-quality materials can withstand varying pressures and corrosive environments, minimizing wear and tear. Additionally, the design must ensure minimal flow resistance while providing accurate regulation, allowing for a more stable flow rate and reducing energy loss.

Another significant factor is the valve’s positioning and installation within the system. Proper placement ensures optimal flow management and reduces turbulence, which can disrupt performance. Furthermore, factors such as temperature and fluid characteristics play a crucial role. For instance, a higher viscosity fluid may require a different valve specification than a lower viscosity one to maintain efficiency. By understanding and optimizing these factors, engineers can enhance the reliability and performance of flow regulator valves, ensuring efficient operation in their intended applications.

Common Challenges in Maintaining Flow Regulator Efficiency

Maintaining the efficiency of flow regulator valves is crucial for optimal system performance, yet several common challenges can hinder this process. One of the primary issues is sediment buildup caused by fluid impurities. This accumulation can restrict flow and disrupt pressure regulation. Regular maintenance, including flushing and cleaning the valve, can help mitigate this problem.

**Tip:** Schedule routine inspections to identify early signs of sediment buildup and consider installing filtration systems to reduce impurities in the fluid before reaching the valve.

Another challenge is temperature fluctuations that may impact valve performance. Extreme temperatures can lead to material fatigue or degradation, affecting the regulator's responsiveness. Choosing valves made from high-quality materials designed for specific temperature ranges is essential.

**Tip:** Monitor the operating environment closely and assess whether thermal insulation or temperature control measures are necessary to protect the valve.

Additionally, calibration and adjustment issues can arise, particularly in older systems where components may have worn over time. Regularly revisiting the calibration settings ensures the valve operates within its optimal range, improving efficiency.

**Tip:** Keep a detailed log of maintenance activities and adjustments to assist in troubleshooting and ensure the valve remains in peak working condition.

Flow Regulator Valve Performance and Efficiency

Best Practices for Optimizing Flow Regulator Valve Operation

Optimizing the operation of flow regulator valves is essential for maintaining system efficiency and performance in various applications. One of the best practices is to ensure proper sizing and selection of the valve based on the specific requirements of the system. An incorrectly sized valve can lead to inefficient flow regulation, causing potential damage to the system and increased operating costs. Therefore, it is vital to measure flow rates accurately and select a valve type that corresponds to the needs of the application, taking into account factors such as fluid properties, pressure requirements, and required flow rates.

Regular maintenance and testing of flow regulator valves are crucial to their optimal performance. Implementing a routine schedule for inspection allows for early detection of wear or malfunctions that could hinder efficiency. Ensuring that the valve is clean and free from debris helps maintain accurate flow regulation, while periodic calibration can help align the valve’s settings with system requirements. Additionally, considering advanced technologies like digital flow measurement and automated control systems can enhance the operation of flow regulator valves, providing real-time feedback and adjustments to improve overall system performance.

Innovative Technologies Enhancing Flow Regulator Performance

In the quest for enhanced flow regulator valve performance and efficiency, innovative technologies play a vital role. For instance, the integration of smart sensors and IoT connectivity is revolutionizing real-time monitoring capabilities. According to a report from the American Society of Mechanical Engineers, implementing advanced sensors can increase the efficiency of fluid management systems by up to 30%. These technologies allow operators to quickly identify issues such as pressure drops or blockages, ultimately minimizing downtime and maintenance costs.

Incorporating machine learning algorithms is another emerging trend that positively impacts flow regulation. These systems optimize valve performance by predicting when adjustments are needed, based on historical data. A study by the International Journal of Fluid Mechanics indicates that systems equipped with machine learning can achieve a remarkable 25% improvement in energy efficiency.

Tip: Consider upgrading to a flow regulator that includes smart technology for real-time monitoring to ensure optimal operation and maintenance efficiency.

As innovative materials, such as composite polymers, continue to enter the market, the durability and reliability of flow regulator valves are on the rise. These materials resist corrosion and wear, extending the lifespan of the valves and reducing total lifecycle costs.

Tip: Evaluate your current valve materials and consider switching to advanced composites for improved longevity and performance.

Evaluating Flow Regulator Valves: Metrics and Testing Methods

When evaluating flow regulator valves, it is essential to establish precise metrics and adopt effective testing methods to ensure their performance aligns with operational requirements. Key performance indicators typically include flow rate, pressure drop, and response time, each providing valuable insights into how well the valve regulates fluid dynamics. By utilizing standardized testing procedures, such as the orifice plate method and dynamic flow testing, manufacturers can accurately assess valve efficiency and reliability under various conditions.

Moreover, real-time monitoring technologies, including flow measurement sensors and pressure transducers, contribute to a comprehensive evaluation. These tools enable technicians to capture data continuously, facilitating a more nuanced understanding of the valve's behavior over time. It is also beneficial to simulate different operational scenarios during testing, allowing for identification of potential failure points and optimization of the valve design. By integrating these metrics and testing methods, stakeholders can enhance the performance and longevity of flow regulator valves, ultimately improving system efficiency.

Related Posts

-

Navigating Global Standards: The Impact of Import and Export Certifications on Best Flow Regulator Valve Supply Chains

-

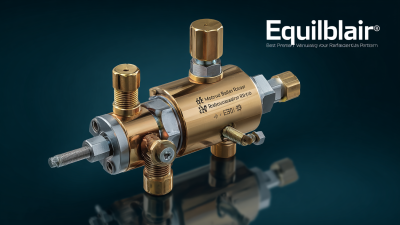

Maximizing Value with Best Equilibar Back Pressure Regulator Through Superior After Sales Service and Low Repair Costs

-

Maximizing Value: After-Sales Support and Maintenance Savings for the Best Low Pressure Regulators

-

Choosing Quality Manufacturers for the Best Steam Pressure Reducing Valve Solutions

-

Unveiling the Best High Pressure Regulator Options for Global Buyers

-

Ultimate Guide to Best Flow Control Valve Innovations and Future Trends in 2025