What is the Functionality and Importance of Equilibar Back Pressure Regulator

In the realm of fluid dynamics and pressure control, the Equilibar Back Pressure Regulator emerges as a crucial component for maintaining system integrity and performance. Reports from industry experts indicate that effective pressure regulation can enhance system efficiency by up to 30%, significantly improving operational reliability. The unique design of the Equilibar Back Pressure Regulator facilitates precise control under varying flow conditions, ensuring stable process outputs. As industries increasingly demand enhanced efficiency and reduced operational costs, the significance of robust pressure regulation solutions becomes apparent. An understanding of the functionality and role of the Equilibar Back Pressure Regulator is essential for engineers and operators seeking to optimize their systems and maintain compliance with stringent regulatory standards.

Understanding the Basics of Equilibar Back Pressure Regulators

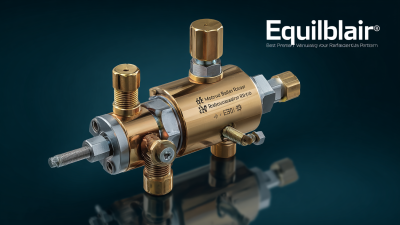

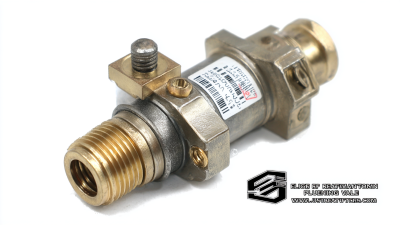

Equilibar back pressure regulators are essential devices used in a variety of industrial applications to maintain a stable pressure regardless of fluctuating flow rates. Their design utilizes a unique diaphragm mechanism that ensures a consistent output pressure, making them ideal for processes that require precise pressure control. Unlike traditional pressure regulators, Equilibar models can handle varying inlet pressures without the risk of over- or under-pressurization, thereby enhancing system reliability and safety.

Understanding the basics of these regulators reveals their important role in preventing backpressure-related issues in systems like chromatography and reaction vessels. They effectively manage the pressure upstream of the system, allowing for improved process efficiency and product quality. The ability to maintain equilibrium between flow and pressure enables manufacturers to optimize their operations while minimizing waste. By utilizing Equilibar back pressure regulators, industries can achieve greater control over their processes, leading to enhanced performance and cost savings in the long run.

Key Features and Mechanisms Behind Equilibar Regulators

Equilibar back pressure regulators are pivotal in maintaining stable pressure control in various applications, ranging from chemical processing to pharmaceutical manufacturing. Their design employs a unique mechanism that allows them to regulate pressure without the typical issues of traditional regulators, such as hysteresis and inconsistent flow. This functionality is critical, particularly in systems where precise pressure management is essential. Industry reports highlight that systems utilizing advanced back pressure regulators can improve process efficiency by up to 20%, significantly reducing operational costs.

In terms of key features, Equilibar regulators utilize a dome-loaded design that provides a linear response to pressure changes, ensuring accuracy and reliability. Equipped with a low-pressure drop and the ability to handle a wide variety of fluids, these regulators can adapt to diverse operational demands. According to a recent analysis published by a leading industry research firm, customers who switch to advanced back pressure solutions, such as those offered by Equilibar, have seen a notable reduction in maintenance costs by approximately 15-25% over traditional systems.

Tip: When selecting a back pressure regulator, consider the pressure range and fluid compatibility to ensure optimal performance and longevity. Additionally, regular maintenance checks can help identify potential issues early, thereby prolonging the lifespan of the regulator.

Applications of Equilibar Back Pressure Regulators in Various Industries

Equilibar back pressure regulators play a crucial role across various industries by maintaining consistent pressure during critical processes. In the pharmaceutical sector, these regulators ensure precise control over reaction pressures, which is vital for the safety and efficacy of drug manufacturing. By preventing fluctuations, Equilibar regulators help maintain the integrity of sensitive chemical compounds, thereby enhancing product quality and compliance with stringent regulatory standards.

In the oil and gas industry, Equilibar back pressure regulators are employed to manage pressure in pipelines and during drilling operations. Their ability to respond quickly to changes in system pressure helps prevent dangerous surges that can lead to costly failures or accidents. Additionally, these regulators facilitate optimal flow rates, which is essential for maximizing efficiency and minimizing operational risks in high-stakes environments.

The versatility of Equilibar back pressure regulators extends to food and beverage production, where they are utilized to control the pressure during carbonation processes. This ensures that the desired level of fizziness is achieved consistently, enhancing product quality and consumer satisfaction. Overall, the functionality of Equilibar regulators across diverse applications showcases their importance in enhancing safety, efficiency, and quality in industrial processes.

Functionality and Importance of Equilibar Back Pressure Regulators in Various Industries

The Benefits of Using Equilibar Regulators for Process Optimization

Equilibar back pressure regulators are crucial tools in industrial processes, offering precision and reliability that can significantly enhance system performance. One of the primary benefits of using Equilibar regulators is their ability to maintain a constant pressure regardless of flow variations. This ensures that downstream processes operate under optimal conditions, preventing fluctuations that could affect product quality and process efficiency.

Furthermore, Equilibar regulators streamline process optimization by reducing waste and energy consumption. By maintaining consistent pressure control, they minimize the need for additional equipment, such as pressure relief valves or complex control systems, which can complicate operations and increase maintenance costs. Their simple, yet effective design contributes to a more straightforward setup that can be adapted to various applications, from chemical manufacturing to pharmaceuticals, ultimately leading to better resource management and improved overall productivity.

Comparison of Equilibar Regulators to Traditional Pressure Control Solutions

Equilibar back pressure regulators (BPRs) represent a significant advancement over traditional pressure control solutions, particularly in applications requiring high precision. Unlike conventional regulators that can suffer from droop and hysteresis, Equilibar BPRs maintain a constant back pressure through a unique diaphragm and force-balance mechanism. According to a report by the American Society of Mechanical Engineers, traditional pressure regulators can experience variations as high as 15% in set point under fluctuating flow conditions. In contrast, Equilibar regulators offer a tighter control, boasting a variance of only 1-2%, which is crucial in industries like pharmaceuticals and chemical processing where maintaining optimal conditions is imperative.

Moreover, the adaptability and reliability of Equilibar regulators make them suitable for a diverse range of applications. A recent market analysis by Research and Markets highlights that the demand for precise pressure control devices is surging, projected to grow at a compound annual growth rate (CAGR) of 8.2% through 2027. With their ability to handle larger flow rates and maintain stable pressure across varying conditions, Equilibar regulators are increasingly seen as the preferred solution. By eliminating the complexities associated with traditional devices, they optimize process efficiency and enhance product quality, making them an essential tool in modern industrial applications.

What is the Functionality and Importance of Equilibar Back Pressure Regulator - Comparison of Equilibar Regulators to Traditional Pressure Control Solutions

| Feature | Equilibar Back Pressure Regulator | Traditional Pressure Control Solutions |

|---|---|---|

| Pressure Stability | High stability across varying flow rates | Moderate stability, often fluctuates |

| Response Time | Instantaneous adjustment | Slower response due to mechanical lag |

| Size and Weight | Compact design | Bulky and heavier |

| Maintenance | Low maintenance requirements | Higher maintenance needs |

| Cost Efficiency | Cost effective in applications with varying pressure needs | Can be more expensive over time due to maintenance and inefficiencies |

| Application Versatility | Widely adaptable to various processes | Limited applications |

Related Posts

-

Maximizing Value with Best Equilibar Back Pressure Regulator Through Superior After Sales Service and Low Repair Costs

-

Finding the Ideal Manufacturer for Best Pressure Reducing Valves in Your Industry

-

Hydraulic Pressure Regulator Innovations Highlighted at Canton Fair 2025 with Record International Buyer Attendance

-

Unveiling the Best High Pressure Regulator Options for Global Buyers

-

Maximizing Value: After-Sales Support and Maintenance Savings for the Best Low Pressure Regulators

-

Discover Elite Manufacturing from a Leading Chinese Factory: Your Source for the Best Pressure Reducing Valve