The Future of Innovative Pneumatic Control Valve Solutions for Global Buyers

As industries worldwide continue to evolve, the demand for advanced technological solutions becomes increasingly paramount. One such innovation making waves in the manufacturing and automation sectors is the Pneumatic Control Valve. These valves play a crucial role in regulating airflow and controlling pressure in pneumatic systems, enhancing efficiency and performance across various applications. In this blog, we will explore the future of innovative Pneumatic Control Valve solutions tailored for global buyers. We will delve into the latest trends, emerging technologies, and case studies that highlight the transformative impact of these valves on production processes. By understanding the cutting-edge advancements in Pneumatic Control Valves, buyers can make informed decisions that align with their operational needs and drive their businesses forward in an increasingly competitive marketplace.

Emerging Trends in Pneumatic Control Valve Technologies for Global Markets

As the global demand for automotive HVAC systems continues to rise, the pneumatic control valve market is experiencing significant transformation. Emerging trends indicate an increasing integration of smart technologies aimed at enhancing system efficiency and user comfort. According to recent market analysis, the automotive HVAC system market is projected to grow at a CAGR of over 7% from 2023 to 2030, driven by the growing demand for fuel-efficient vehicles and stringent regulatory standards.

One of the pivotal components in this evolving landscape is the pneumatic control valve, which plays a critical role in regulating airflow and temperature within automotive HVAC systems. Innovative designs, including the implementation of advanced materials and digital control mechanisms, are being adopted to improve response times and reliability. Industry reports suggest that advancements in valve technologies can lead to improved energy efficiency, which is essential for manufacturers aiming to meet sustainability goals while also enhancing vehicle performance.

Moreover, the shift towards electric and hybrid vehicles is fueling a demand for more sophisticated and compact pneumatic control valves. These systems not only facilitate the management of internal climate but also contribute to the overall vehicle weight reduction, a key factor in enhancing energy efficiency. As automotive manufacturers increasingly prioritize innovation and performance, the evolution of pneumatic control valve technologies will be crucial in meeting global market demands.

Integrating Digital Solutions in Pneumatic Control for Enhanced Performance

The integration of digital solutions in pneumatic control systems is revolutionizing the way industries operate, driving enhanced performance and efficiency. According to a recent market report by Frost & Sullivan, the pneumatic valve market is expected to grow by 5.3% annually, with digital technologies playing a pivotal role in this growth. By leveraging smart sensors and IoT capabilities, companies can monitor valve performance in real time, reducing downtime and maintenance costs significantly.

Furthermore, the adoption of advanced data analytics enables predictive maintenance strategies that can enhance operational reliability. A study by McKinsey indicates that implementing such digital solutions can increase system efficiency by up to 15%, translating into substantial cost savings for manufacturers. With the growing focus on automation and Industry 4.0, the demand for innovative pneumatic control valve solutions integrating these digital technologies is set to soar. This shift not only improves productivity but also supports sustainability initiatives by optimizing energy consumption, setting the stage for a future where efficiency and environmental responsibility go hand in hand.

Exploring Top Manufacturers and Their Innovative Valve Designs

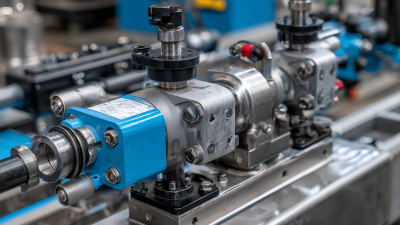

The landscape of industrial automation is rapidly evolving, and pneumatic control valves are at the forefront of this transformation. As industries seek more efficient and reliable systems, top manufacturers are responding with innovative valve designs that enhance performance while minimizing downtime. These cutting-edge solutions incorporate advanced materials and technology, ensuring durability and precision under varying pressures and temperatures.

Manufacturers are focusing on user-friendly designs that simplify installation and maintenance. For instance, smart pneumatic valves equipped with IoT connectivity allow for real-time monitoring and data collection, enabling users to optimize their operations dynamically. Companies like Parker Hannifin and SMC Corporation have pioneered such integrations, making their products indispensable for global buyers looking to modernize their automation processes.

Furthermore, sustainability is a growing concern among manufacturers, leading to the development of eco-friendly valve solutions. By leveraging energy-efficient technologies and recyclable materials, these manufacturers not only meet current environmental standards but also appeal to a market increasingly focused on sustainability. As the global demand for pneumatic control valves continues to rise, staying informed about these innovative designs is crucial for buyers aiming to stay competitive in their sectors.

The Role of Sustainability in the Future of Pneumatic Control Valves

The growing emphasis on sustainability is reshaping the future of pneumatic control valves, making it an essential consideration for manufacturers and global buyers. As industries strive to reduce their carbon footprints, the demand for energy-efficient valve solutions is on the rise. These innovations not only optimize performance but also align with broader environmental goals. By utilizing materials and designs that minimize waste and energy consumption, manufacturers can create products that serve both operational needs and sustainability objectives.

Moreover, advancements in technology are enabling the development of pneumatic control valves that incorporate smart features, such as real-time monitoring and automation. This not only enhances efficiency but also provides crucial data that can help businesses make more informed decisions regarding their energy use and environmental impact. Sustainable practices in production and operation of pneumatic control valves are not merely trends but necessities that can lead to significant long-term benefits, both ecologically and economically. As global buyers become more conscious of these factors, the industry must adapt and innovate, ensuring that future solutions meet the demands of a more sustainable world.

The Future of Innovative Pneumatic Control Valve Solutions for Global Buyers - The Role of Sustainability in the Future of Pneumatic Control Valves

| Dimension | Current Trends | Future Outlook | Sustainability Impact |

|---|---|---|---|

| Technological Advances | Integration of IoT | Increased automation and smart features | Reduced energy consumption |

| Material Innovation | Use of lightweight alloys | Biodegradable components | Lower environmental footprint |

| Customer Demand | Focus on energy efficiency | Demand for customizable solutions | Alignment with CSR goals |

| Regulatory Changes | Stricter emissions standards | Increased compliance requirements | Encouragement of eco-friendly products |

| Global Market Trends | Growth in renewable energy sectors | Emerging markets driving demand | Support for sustainable practices |

Impact of Automation and IoT on Pneumatic Control Valve Efficiency

The integration of Automation and the Internet of Things (IoT) has profoundly transformed the efficiency of pneumatic control valves, heralding a new era for global buyers. According to a recent report by MarketsandMarkets, the global pneumatic control valve market is projected to reach $3.91 billion by 2025, driven significantly by advancements in automation technologies. Implementing IoT solutions allows for real-time monitoring and control of pneumatic systems, improving response times and reducing operational costs.

To optimize performance, consider incorporating intelligent sensors that provide data on valve position and pressure. This real-time feedback loop allows for predictive maintenance, which can cut downtime by up to 30%, according to a study by the International Society of Automation. Additionally, leveraging machine learning algorithms can drastically enhance the decision-making process, leading to smarter and more efficient operational strategies.

Tip: When selecting pneumatic control valves, prioritize those that are IoT-enabled. This feature not only facilitates seamless connectivity but also enhances the accuracy of data collection, leading to better-informed decisions. Furthermore, aim for valves designed for easy integration with existing systems to maximize your current infrastructure's potential.

Related Posts

-

Choosing Quality Manufacturers for the Best Steam Pressure Reducing Valve Solutions

-

Ultimate Guide to Choosing the Best Hydraulic Pressure Regulator for Your Needs

-

Ultimate Guide to Best Flow Control Valve Innovations and Future Trends in 2025

-

Discover the Excellence of China's Leading Manufacturer: The Best Air Flow Control Valve

-

Navigating Global Trade Certification for Best Hydraulic Pressure Reducing Valve Procurement

-

Unveiling the Best High Pressure Regulator Options for Global Buyers