Understanding the Role of Hydraulic Pressure Reducing Valves in Modern Engineering Solutions

In contemporary engineering solutions, the Hydraulic Pressure Reducing Valve (HPRV) is pivotal in optimizing system performance and enhancing safety. According to a report by the International Society of Automation, the implementation of pressure management systems, which prominently feature HPRVs, has been shown to increase energy efficiency by up to 30% in industrial applications. Furthermore, a study conducted by the Fluid Power Journal estimates that proper pressure regulation can lead to significant operational cost savings, potentially exceeding $50,000 annually in large-scale hydraulic systems. As industries evolve towards more sustainable and efficient practices, understanding the crucial role of HPRVs becomes imperative for engineers seeking to mitigate risks associated with excessive pressure and improve overall system reliability. With the global hydraulic components market projected to reach $50 billion by 2026, the demand for effective HPRVs will only continue to grow, underscoring their significance in modern engineering endeavors.

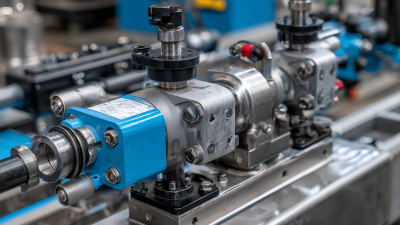

The Functionality of Hydraulic Pressure Reducing Valves Explained

Hydraulic pressure reducing valves play a critical role in modern engineering solutions by managing and regulating fluid pressure within hydraulic systems. These valves ensure that the downstream pressure remains stabilized, allowing machinery to operate safely and efficiently. By automatically adjusting the flow of hydraulic fluid, they protect sensitive components from excessive pressure, thereby enhancing the longevity and reliability of equipment.

Tip: When selecting a hydraulic pressure reducing valve, consider the system's pressure requirements and flow rates. It's essential to choose a valve that can handle the maximum expected pressure fluctuations while providing a stable downstream environment.

In addition to providing pressure reduction, these valves can improve system performance. They reduce energy losses and help in maintaining optimal operating conditions, which is particularly beneficial in applications that require precise control. Understanding the specific functionality of hydraulic pressure reducing valves can help engineers design more sophisticated and efficient hydraulic systems.

Tip: Regular maintenance and inspection of these valves are crucial for ensuring their proper functioning and prolonging their lifespan. Install pressure gauges to monitor performance and replace any worn components promptly to avoid system failures.

Benefits of Using Pressure Reducing Valves in Modern Systems

Pressure reducing valves (PRVs) play a crucial role in modern engineering solutions by efficiently managing hydraulic systems. One of the primary benefits of using PRVs is their ability to maintain consistent pressure levels throughout a system. This is vital in applications where pressure fluctuations can lead to equipment damage or inefficient operation. By ensuring a steady flow of fluid at the required pressure, PRVs help enhance system reliability, thereby reducing maintenance costs and downtime.

Moreover, PRVs contribute significantly to energy efficiency. By regulating pressure, they help minimize energy losses that can occur due to excessive pressure in hydraulic systems. This not only leads to lower operational costs but also supports sustainability initiatives by reducing the overall energy consumption of the system. The integration of pressure reducing valves in modern systems thus results in a more optimized, cost-effective, and environmentally friendly approach to engineering design.

Understanding the Role of Hydraulic Pressure Reducing Valves in Modern Engineering Solutions - Benefits of Using Pressure Reducing Valves in Modern Systems

| Dimension | Description | Benefits | Applications |

|---|---|---|---|

| Flow Rate | The volume of fluid that can pass through the valve per unit time. | Optimizes system efficiency and reduces energy costs. | Industrial hydraulic systems, water distribution. |

| Pressure Setting | The pressure level at which the valve operates effectively. | Ensures equipment protection and longevity. | Manufacturing processes, agricultural machinery. |

| Material | The type of material used in the valve construction. | Enhances durability and resistance to corrosion. | Chemical processing, food and beverage industry. |

| Adjustment Method | How the valve pressure is adjusted, e.g., manual, automatic. | Allows for flexibility and precise control in operations. | Robotic systems, HVAC applications. |

| Size | Physical dimensions of the valve. | Facilitates integration in various system architectures. | Construction machinery, automotive systems. |

Key Applications of Hydraulic Pressure Reducing Valves in Engineering

Hydraulic pressure reducing valves play a crucial role in modern engineering solutions by managing and controlling the pressure within hydraulic systems. These valves ensure that the operating pressure remains within safe and efficient limits, thereby protecting equipment and enhancing performance. One significant application is in construction machinery, where pressure reducing valves help regulate the power delivered to various components, improving the overall efficiency and reliability of the machinery.

Hydraulic pressure reducing valves play a crucial role in modern engineering solutions by managing and controlling the pressure within hydraulic systems. These valves ensure that the operating pressure remains within safe and efficient limits, thereby protecting equipment and enhancing performance. One significant application is in construction machinery, where pressure reducing valves help regulate the power delivered to various components, improving the overall efficiency and reliability of the machinery.

Another vital application is found in the automotive industry, particularly in hydraulic braking systems. Pressure reducing valves help modulate the pressure applied to the brakes, ensuring smooth and effective stopping power. By preventing excessive pressure, these valves enhance safety and prolong the lifespan of braking components. Additionally, in industrial automation, pressure reducing valves facilitate precise control in hydraulic circuits, leading to optimized operations in manufacturing processes. Overall, their versatility and effectiveness make hydraulic pressure reducing valves indispensable in diverse engineering sectors.

Factors Influencing the Selection of Pressure Reducing Valves

In modern engineering applications, the selection of hydraulic pressure reducing valves (PRVs) is influenced by several crucial factors that ensure optimal system performance and reliability. One of the primary considerations is the valve's pressure rating, which must align with the operational pressure of the system. According to a recent report from the Hydraulic Regulatory Association, approximately 45% of system failures are attributed to mismatched pressure ratings, underscoring the importance of accurate selection.

Another significant factor is the flow capacity of the valves. Engineers must evaluate the specific flow requirements of their systems, often relying on data from flow modeling simulations. The same industry report highlights that inadequate flow capacity can lead to pressure drops exceeding 20%, ultimately compromising system efficiency and safety. Additionally, the valve's materials and construction are essential considerations; corrosion resistance and compatibility with hydraulic fluids are paramount, especially in industries such as oil and gas, where environmental conditions can be harsh. Selecting PRVs with appropriate material properties can drastically reduce maintenance costs and extend service life, making it a vital step in modern engineering design.

Understanding the Role of Hydraulic Pressure Reducing Valves

This chart illustrates key parameters of hydraulic pressure reducing valves, such as flow rate, maximum pressure, inlet pressure, and outlet pressure. Understanding these factors is essential for selecting the appropriate valve for modern engineering solutions.

Maintenance Practices to Ensure Optimal Performance of Valves

To ensure optimal performance of hydraulic pressure reducing valves, regular maintenance practices are essential. These valves play a crucial role in regulating pressure in hydraulic systems, and any malfunction can lead to inefficiencies or even system failures. Routine inspections should include checking for leaks, assessing the valve's response to pressure changes, and ensuring that all components, such as seals and diaphragms, are in good condition. Keeping the system clean and free from contaminants is equally important, as dirt and debris can impair valve functionality.

Furthermore, calibration of the pressure settings is vital for maintaining accuracy and efficiency. Over time, valves may drift from their intended settings due to wear or environmental factors. Regular recalibration ensures that the valves function within the desired pressure range, providing reliability in performance. Documenting maintenance activities, including replacement schedules and performance logs, can also help identify patterns and predict when further interventions may be necessary, ultimately prolonging the life of the hydraulic pressure reducing valves.

Related Posts

-

Navigating Global Trade Certification for Best Hydraulic Pressure Reducing Valve Procurement

-

Finding the Ideal Manufacturer for Best Pressure Reducing Valves in Your Industry

-

Ultimate Guide to Choosing the Best Hydraulic Pressure Regulator for Your Needs

-

Unmatched Innovation in Best Air Flow Control Valves from China's Leading Manufacturing Plants

-

The Future of Innovative Pneumatic Control Valve Solutions for Global Buyers

-

What is the Functionality and Importance of Equilibar Back Pressure Regulator