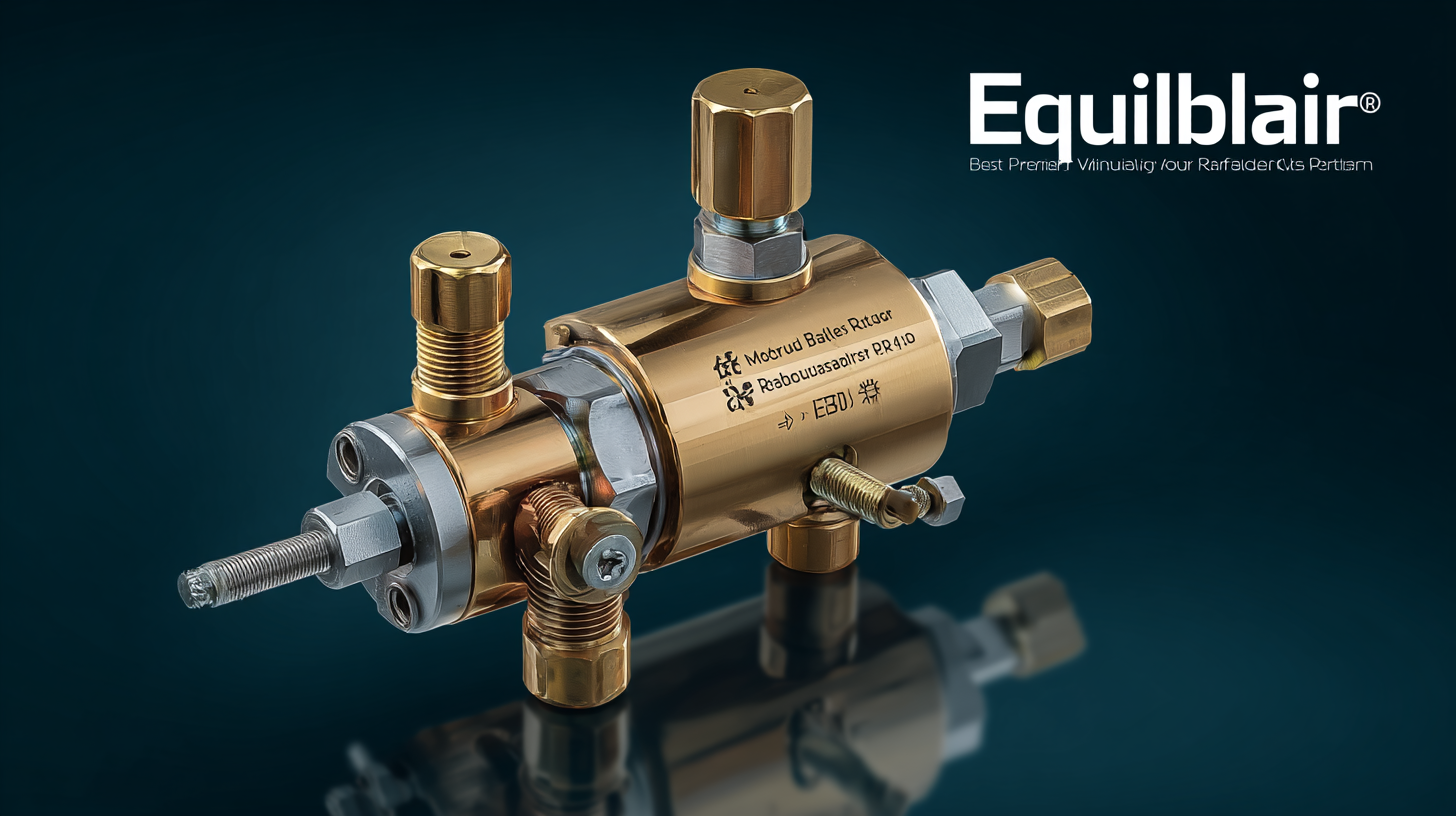

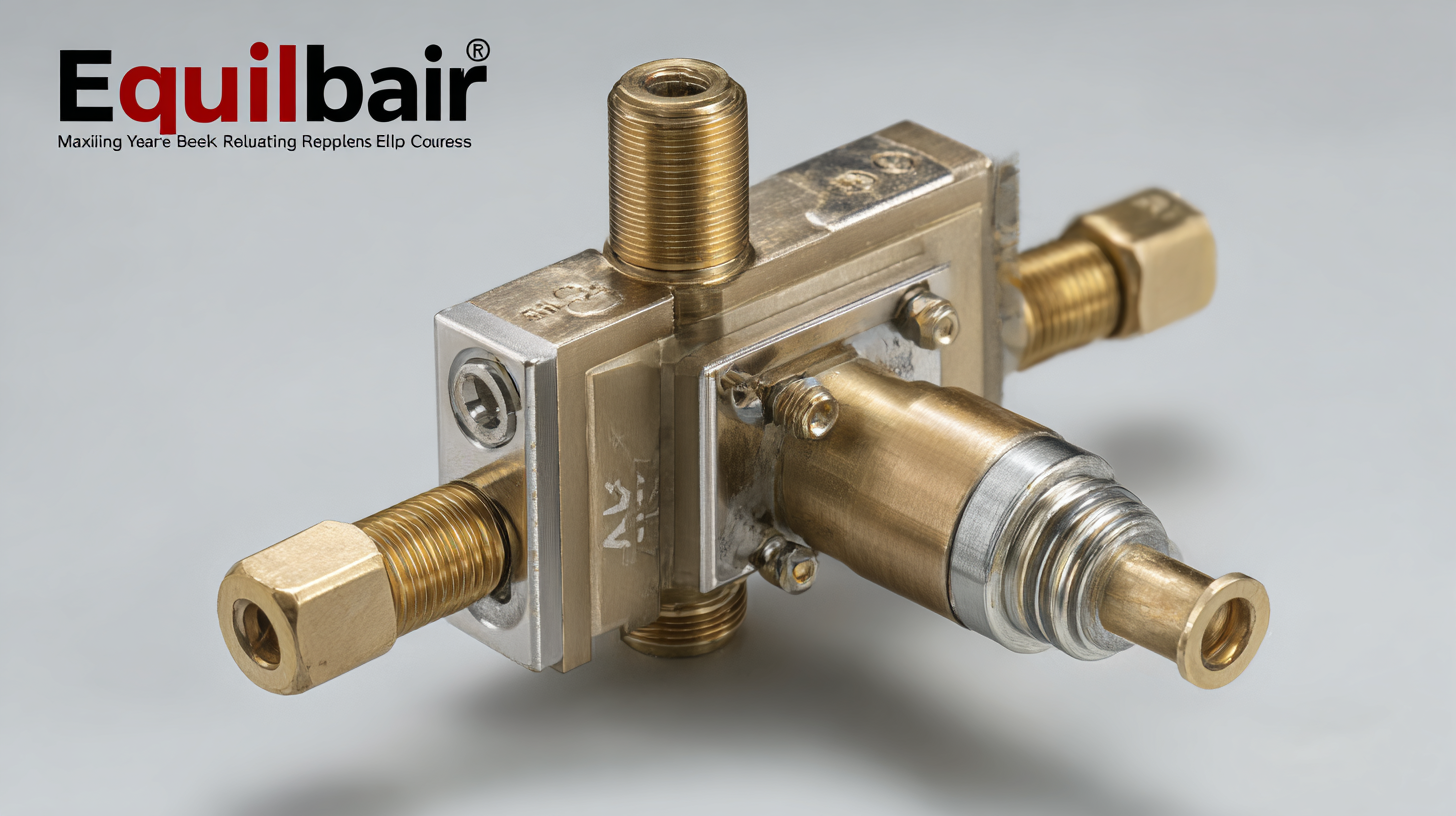

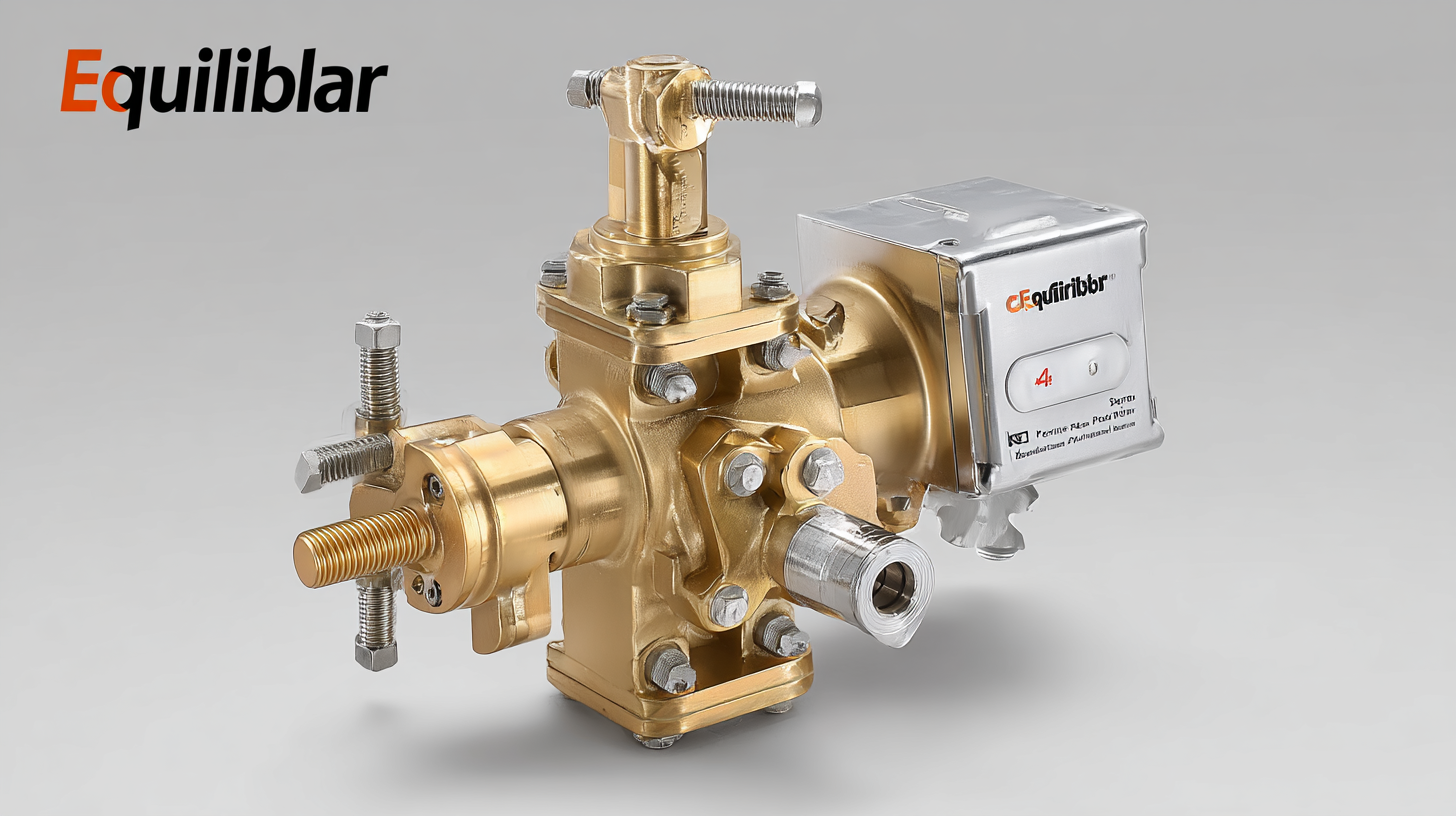

Maximizing Value with Best Equilibar Back Pressure Regulator Through Superior After Sales Service and Low Repair Costs

In today's competitive industrial landscape, optimizing performance while minimizing costs is paramount for businesses aiming for long-term sustainability. The Equilibar Back Pressure Regulator has emerged as a key component in this quest, offering precision control and unparalleled reliability across various applications. According to a recent industry report, the market for pressure regulators is anticipated to grow significantly, with a projected CAGR of 6.1% from 2023 to 2028. This growth signals an increasing reliance on advanced technologies like the Equilibar Back Pressure Regulator, which not only enhances operational efficiency but also reduces overall maintenance expenses. By leveraging superior after-sales service and low repair costs, companies can maximize the value derived from their equipment, ultimately driving profitability and operational excellence. With increasing demands for effective pressure management in sectors ranging from pharmaceuticals to petrochemicals, the ability to implement cost-effective solutions while ensuring system integrity is undeniably crucial.

Understanding the Importance of After Sales Service in Back Pressure Regulators

After-sales service is a crucial element in ensuring the longevity and optimal performance of back pressure regulators. In the competitive landscape of industrial equipment, customers expect not only high-quality products but also comprehensive support once the product is delivered. A well-structured after-sales service program can significantly enhance user satisfaction, reinforcing the reliability of brands like Equilibar. Effective support can include troubleshooting, maintenance advice, and rapid response to any potential issues that may arise, all of which contribute to minimizing downtime and ensuring that systems operate at peak efficiency.

Moreover, low repair costs associated with quality after-sales service can make a significant difference for businesses relying on these devices. When manufacturers invest in providing robust after-sales support, they can better manage repairs and replacements while fostering a trustful relationship with customers. This emphasis on customer care not only enhances user experience but also translates into long-term value creation—an essential aspect for companies aiming to maximize their return on investment in back pressure regulators.

Maximizing Value with Back Pressure Regulators: A Focus on After Sales Service

Cost-Effectiveness: Why Low Repair Costs Matter for Your Business

To achieve net zero emissions, local authorities must focus not only on transitioning to zero-emission fleets but also on ensuring that operational costs remain manageable. Research indicates that the upfront investment in electric fleet vehicles can result in savings of approximately 50% in fuel and maintenance costs over their lifespan. This highlights how transitioning to greener alternatives can be financially viable, especially when paired with systems that reduce ongoing expenses.

To achieve net zero emissions, local authorities must focus not only on transitioning to zero-emission fleets but also on ensuring that operational costs remain manageable. Research indicates that the upfront investment in electric fleet vehicles can result in savings of approximately 50% in fuel and maintenance costs over their lifespan. This highlights how transitioning to greener alternatives can be financially viable, especially when paired with systems that reduce ongoing expenses.

In the context of maximizing cost-effectiveness, companies that perform rotor repairs can further enhance their financial standing through strategic partnerships. For instance, utilizing specialized brake solutions can significantly cut repair costs, leading to improved profit margins. Data shows that effective rotor repair strategies can save fleets up to 30% when considering maintenance budgets and downtime. With local councils keenly mindful of budget constraints, these efficiencies are crucial as they strive to meet sustainability goals without sacrificing financial stability.

Moreover, the ongoing costs associated with implementing new technologies, such as direct air capture systems, underscore the importance of cost-effectiveness in achieving environmental targets. As technologies mature, it's anticipated that costs could stabilize at about $100-600 per ton of CO2, primarily due to capital cost reductions. Thus, investing in solutions that not only reduce emissions but also lower overall operational costs is essential for local authorities aiming to fulfill their commitments to a sustainable future.

The Role of Quality Assurance in Global Market Success for Made-in-China Products

In today's competitive landscape, quality assurance plays a pivotal role in securing global market success for made-in-China products. When manufacturers prioritize quality assurance, they establish a reputation for reliability that resonates with consumers worldwide. This commitment not only enhances brand trust but also sets a foundation for long-term customer relationships. By meticulously examining every stage of production, companies can identify potential issues before they escalate into significant problems, ultimately leading to increased customer satisfaction.

Tip: Implementing a robust quality management system can streamline production processes and minimize defects. Regular training for staff on quality standards ensures that everyone is aligned with the company's commitment to excellence.

Furthermore, effective quality assurance practices can significantly reduce repair costs and lower the total cost of ownership for customers. For example, companies that invest in durable materials and thorough testing protocols can avoid the pitfalls of frequent repairs and replacements, thus maximizing value for consumers. As the demand for high-quality products rises, ensuring quality at every level of production will not only attract buyers but maintain customer loyalty.

Tip: Collecting feedback from customers post-sale can provide invaluable insights for continuous improvement in product quality and service. Regularly engaging with consumers allows companies to adapt to changing market needs and preferences.

Enhancing Customer Satisfaction Through Reliable Technical Support

In today’s competitive landscape, enhancing customer satisfaction through reliable technical support has become a cornerstone for businesses striving to maintain a loyal client base. Effective after-sales service not only resolves issues quickly but also instills confidence in customers. When it comes to equipment such as the Equilibar Back Pressure Regulator, the provision of prompt and expert technical assistance can significantly impact a customer’s experience. By offering comprehensive training and resources, companies empower users to operate their systems efficiently, thereby maximizing the value derived from their purchases.

Moreover, low repair costs associated with the Equilibar Back Pressure Regulator can greatly contribute to overall customer satisfaction. When customers know that they can access affordable repairs and replacements, the perceived risk of investing in high-quality equipment diminishes. This assurance fosters a lasting relationship between the business and its customers, as they feel supported throughout the lifecycle of the product. Ultimately, prioritizing reliable technical support and minimizing repair expenses creates a win-win scenario for both the company and its clientele, driving success and loyalty in the long term.

How Equilibar’s Back Pressure Regulators Stand Out in Performance and Reliability

Equilibar's back pressure regulators have increasingly set the benchmark in performance and reliability within the fluid control industry. According to a report by the Control Valve Institute, about 40% of valve failures can be attributed to inadequate back pressure management. Equilibar’s innovative design addresses this challenge by offering dynamic response capabilities that minimize pressure fluctuations, thus ensuring consistent operational efficiency. Their regulators can respond to changes in process conditions rapidly, maintaining optimal performance even under demanding scenarios.

Equilibar's back pressure regulators have increasingly set the benchmark in performance and reliability within the fluid control industry. According to a report by the Control Valve Institute, about 40% of valve failures can be attributed to inadequate back pressure management. Equilibar’s innovative design addresses this challenge by offering dynamic response capabilities that minimize pressure fluctuations, thus ensuring consistent operational efficiency. Their regulators can respond to changes in process conditions rapidly, maintaining optimal performance even under demanding scenarios.

In terms of reliability, industry data indicates that devices with improved materials and construction quality, like Equilibar's regulators, demonstrate a significant reduction in lifetime maintenance costs—up to 30% less than competitors. The use of high-quality synthetic elastomers and robust fittings in Equilibar products not only enhances durability but also extends service intervals, thereby providing users with peace of mind and lower overall repair expenses. This remarkable blend of performance and reliability positions Equilibar’s back pressure regulators as the go-to solution for industries requiring stringent control over their fluid systems.