What is a Steering Cylinder and How Does It Work?

The Steering Cylinder is a crucial component in hydraulic steering systems. It plays a vital role in ensuring a vehicle’s maneuverability and stability. According to industry studies, over 70% of modern vehicles now utilize hydraulic steering systems. This highlights the importance of the Steering Cylinder in contemporary automotive design.

In essence, the Steering Cylinder converts hydraulic pressure into mechanical force. This enables vehicles to turn with precision and ease. However, it is essential to recognize that not all systems are flawless. Maintenance issues and wear over time can lead to performance declines. In fact, research indicates that nearly 30% of steering system failures are linked to faulty cylinders. This statistic draws attention to the need for regular checks and balances.

Moreover, understanding the workings of this device can enhance safety. Users should be aware of how steering responsiveness can vary with different models. The design and efficiency of the Steering Cylinder may impact overall driving experience. Awareness can lead to better decision-making, ensuring that vehicles function at their best throughout their lifespan.

What is a Steering Cylinder?

A steering cylinder is a crucial component in hydraulic steering systems. It controls the direction of a vehicle by converting hydraulic pressure into mechanical movement. Simply put, it's the part that helps turn the wheels when you steer. Most vehicles use this system because it provides better control and responsiveness.

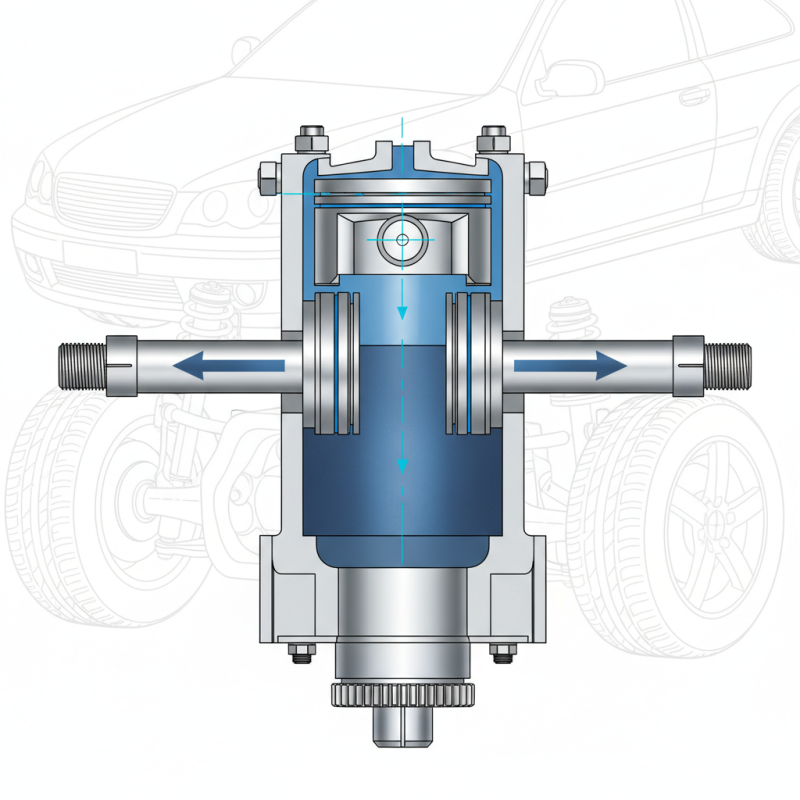

When the driver turns the steering wheel, hydraulic fluid moves into the cylinder. This action pushes the piston, which then moves the steering linkage. As a result, the wheels pivot in the desired direction. This mechanism makes steering easier, especially in larger vehicles. However, if the cylinder fails, it can lead to serious steering issues. Drivers must stay attentive to how their vehicle responds.

Maintaining the steering cylinder is important. Sometimes it can develop leaks or suffer from wear and tear. These problems often go unnoticed until an issue arises. Regular checks can prevent accidents. It's essential to understand that while the steering cylinder enhances driving, it is not infallible. Awareness of its functionality can lead to safer driving experiences.

Key Components of a Steering Cylinder

A steering cylinder is a crucial component in hydraulic steering systems. It converts hydraulic pressure into motion, allowing precise steering control. Understanding its key components can enhance your knowledge of how these systems function.

At the heart of the steering cylinder is the piston. This cylindrical piece moves within the housing when hydraulic fluid is pumped in. The fluid creates pressure that pushes the piston, causing the linked steering mechanism to turn. Seals are vital as well, preventing leaks and maintaining pressure. If seals wear out, it can lead to system inefficiency.

The rod connected to the piston is another key part. It extends out of the cylinder to connect with the steering linkage. Sometimes, it can be misaligned or damaged due to high stress. This can create difficulty in steering. Moreover, the cylinder’s housing offers necessary protection. A sturdy design should withstand impacts and environmental elements. But, over time, corrosion may weaken it. Regular inspection can help catch these issues early.

Steering Cylinder Key Components Usage

How Steering Cylinders Function in Vehicles

Steering cylinders play a crucial role in vehicle dynamics. They are part of hydraulic steering systems found in many modern cars. These cylinders convert hydraulic pressure into mechanical motion. In essence, they allow drivers to turn the vehicle with ease and precision.

When the driver turns the steering wheel, a pump generates hydraulic pressure. This pressure moves fluid into the steering cylinder. As a result, the cylinder extends or retracts, pushing the steering system to turn the wheels. According to industry reports, nearly 85% of vehicles now use hydraulic or electric steering systems. This has improved responsiveness and control significantly.

Despite advances, some issues persist. For instance, leaks in hydraulic systems can reduce effectiveness. Additionally, wear and tear may affect performance over time. Regular maintenance is essential to ensure optimal function. Drivers sometimes overlook this, which can lead to safety concerns. Understanding how steering cylinders work helps in making informed decisions about vehicle care.

Different Types of Steering Cylinders

Steering cylinders play a crucial role in various vehicles and machinery. They enable the driver's input to translate into the precise movement of wheels. Different types of steering cylinders exist, each serving a specific purpose.

A common type is the hydraulic steering cylinder. It relies on fluid pressure to assist in steering. This system allows for smoother control and less effort to turn the wheel. Another type is the electric steering cylinder. It uses electric motors to adjust steering based on driving conditions. This system is often found in modern cars. It can provide a more responsive and dynamic driving experience.

Mechanical steering cylinders also exist, typically in older vehicles. These rely on physical linkage and manual effort. Though simple, they require more strength and can feel less precise. Ultimately, understanding these types may enhance vehicle performance and user experience. Engaging with the right type can yield better handling and efficiency. Choose wisely.

What is a Steering Cylinder and How Does It Work? - Different Types of Steering Cylinders

| Type of Steering Cylinder | Function | Common Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Hydraulic Steering Cylinder | Uses hydraulic fluid to assist in steering | Heavy machinery, commercial vehicles | High steering force, precise control | Complex system, potential leaks |

| Electric Steering Cylinder | Uses electric motors for steering assistance | Modern passenger cars | Energy-efficient, adjustable steering responses | Dependence on electronic systems, higher cost |

| Mechanical Steering Cylinder | Relies on mechanical linkages for steering | Older vehicle models, bikes | Simplicity, lower maintenance | Heavier, less responsive |

| Power-Assisted Steering Cylinder | Combines manual effort with hydraulic or electric assistance | Most new vehicles | Balanced feel, reduced driver effort | Can be over-assisted, decreasing road feel |

Maintenance and Troubleshooting of Steering Cylinders

Maintaining steering cylinders is essential for safe vehicle performance. Regular inspections can catch issues early. Look for leaks, cracks, or rust. These signs indicate potential failures. Check fluid levels frequently to ensure proper operation. Low fluid can lead to inadequate steering response.

Troubleshooting problems with steering cylinders can be tricky. Unusual noises can suggest poor lubrication. If you notice resistance while turning, it might point to an internal issue. Sometimes, air bubbles in the system can cause steering difficulties. Bleeding the system may be necessary to remove trapped air.

Replacing seals and gaskets is common. They wear out over time and can lead to leaks. Ensure you use the correct dimensions for replacements. Otherwise, it could create more problems. Remember, addressing minor issues promptly prevents larger repairs down the line.